Black mass battery recycling process is a method to recover high-value metals from spent batteries through a series of treatments, including mechanical processing, hydrometallurgical technology, and potential further refinement.

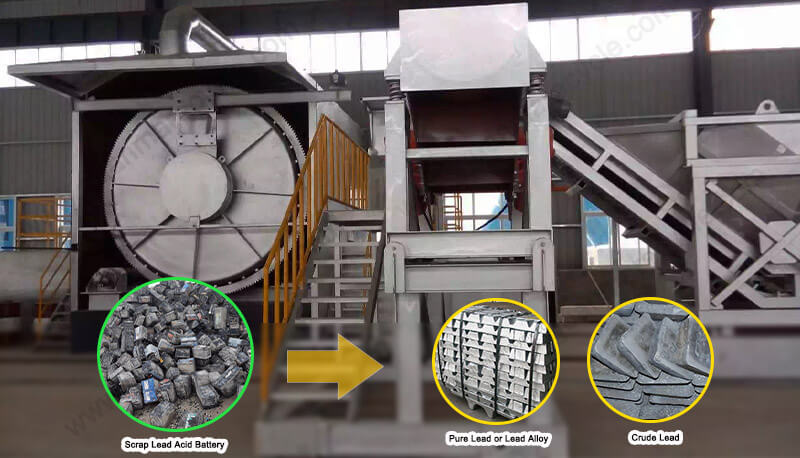

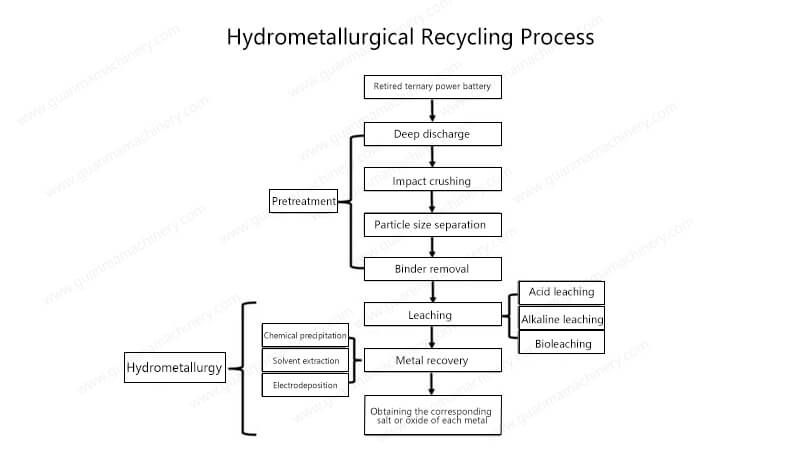

In this process, spent batteries are first mechanically treated, typically involving shredding and incineration, to produce a product known as “black mass”. This black mass contains the metals of interest, such as those used in the cathode, along with ash, graphite, residual electrolyte, and potentially high levels of contaminant elements.

The next step involves the use of advanced technologies, such as hydrometallurgical processing, to extract and refine the valuable metals from the black mass. Companies like Guanma Machinery, for example, utilize proprietary hydrometallurgical technology to recover these metals through an advanced battery black mass recycling process.

This process not only complements the virgin battery metals supply but also reduces the carbon footprint of the battery supply chain, making it a sustainable option.

Once the concentrations of the major elements in the black mass are known, recyclers can further extract and refine the cathode metals, making them available for the production of new batteries. This recycling process helps to close the loop in the battery value chain, promoting circularity and sustainability.

These initiatives aim to maximize the recovery of valuable metals from spent batteries and minimize the environmental impact of battery disposal.