The global shift toward sustainable energy and electric vehicles (EVs) has ignited a critical challenge: how to responsibly recycle lithium-ion batteries. At the heart of this challenge lies black mass battery recycling—a process that extracts valuable metals like lithium, cobalt, and nickel from spent batteries. By 2025, the black mass recycling market is projected to exceed $20 billion, driven by stringent environmental regulations and soaring demand for battery raw materials.

What is Black Mass Battery Recycling?

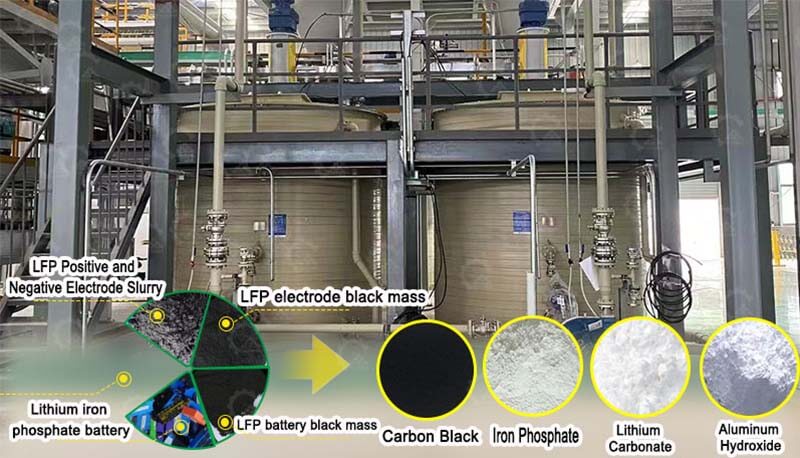

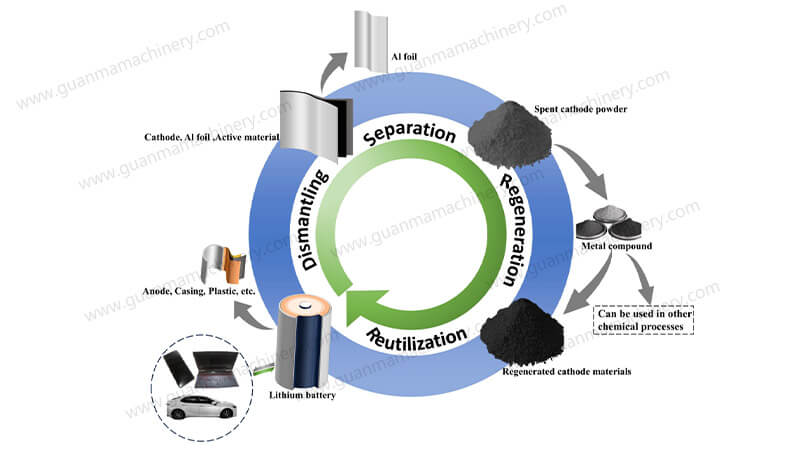

Black mass refers to the shredded material recovered from crushed lithium-ion batteries, containing a mix of precious metals, plastics, and electrolytes. The black mass recycling process involves separating these components to reclaim critical resources, reducing reliance on mining and minimizing hazardous waste. With over 11 million metric tons of batteries expected to reach end-of-life by 2030, recycling black mass is no longer optional—it’s a strategic necessity for businesses and governments alike.

Cutting-Edge Black Mass Recycling Technologies

To stay competitive, companies must adopt efficient and eco-friendly methods. Here are the top technologies dominating the black mass battery recycling market:

1. Hydrometallurgy

Process: Uses chemical solutions (e.g., acids or solvents) to dissolve and recover metals from black mass.

Advantages: High purity (95%+ metal recovery), lower energy consumption, and reduced greenhouse emissions.

Key Term: Black Mass Hydrometallurgy is gaining traction for its scalability and compliance with EU’s Circular Economy Action Plan.

2. Pyrometallurgy

Process: Melts black mass at high temperatures to separate metals.

Drawbacks: High energy costs and air pollution risks.

3. Direct Recycling

Process: Reuses cathode materials without breaking them down chemically.

Emerging Trend: Ideal for EV batteries with minimal degradation.

4. Mechanical Separation

Process: Crushes batteries and uses sieving/magnetic separation to isolate components.

Cost-Effective: Often used as a pre-treatment step before hydrometallurgy.

5 Business Benefits of Investing in Black Mass Recycling

1. Profit from Scarcity

Recovered metals like cobalt ($40,000/ton) and lithium ($70,000/ton) can be resold at premium prices as mining costs rise.

2. Compliance with Global Regulations

The EU’s Battery Regulation (2023) mandates 70% lithium recovery by 2030. Similar laws in the U.S. and Asia reward compliant **black mass recycling companies.

3. Strengthen ESG Credentials

Brands adopting recycling technologies attract ESG-focused investors and eco-conscious clients.

4. Secure Supply Chains

Reduce dependency on geopolitically unstable mining regions.

5. Tap into Government Incentives

Grants, tax breaks, and subsidies are available for sustainable battery recycling projects.

2025 Market Trends: What to Expect

1. Explosive Growth in Asia-Pacific

China, India, and South Korea are investing billions in black mass recycling plants to support their EV and renewable energy sectors.

2. Rise of Hydrometallurgy

Forecasts suggest hydrometallurgical processes will dominate 60% of the market by 2025 due to their efficiency and low carbon footprint.

3. Corporate Partnerships

Automakers are collaborating with black mass recycling companies to create closed-loop supply chains.

4. AI-Driven Optimization

Machine learning is being used to improve metal recovery rates and reduce processing costs.

How to Start a Black Mass Recycling Business

1. Choose the Right Technology

Evaluate factors like feedstock volume, target metals, and regional regulations. Hydrometallurgy suits high-purity demands, while pyrometallurgy works for bulk processing.

2. Partner with Reliable Equipment Suppliers

Invest in modular black mass recycling plants that allow capacity expansion as demand grows.

3. Secure Feedstock and Offtake Agreements

Partner with battery manufacturers, EV dismantlers, and e-waste collectors for steady supply.