The black mass hydrometallurgy machine represents a pivotal advancement in the battery recycling industry, offering a sustainable solution for reclaiming valuable metals from spent lithium-ion batteries. In the burgeoning era of renewable energy and electric mobility, the efficient lithium extraction from black mass is becoming increasingly crucial. This article delves into the significance of black mass processing, the composition of lithium-ion battery black mass, and how GuanMa Machinery contributes to the cutting-edge technology of black mass battery recycling.

The Significance of Black Mass Processing

Black mass is the term given to the residue obtained after the mechanical disassembly and shredding of spent lithium-ion batteries. This heterogeneous material is rich in metals like lithium, cobalt, nickel, and manganese, all of which are essential for the production of new batteries. The battery black mass price reflects its value, driven by the high demand for these metals in the manufacturing sector.

Understanding the Composition of Black Mass

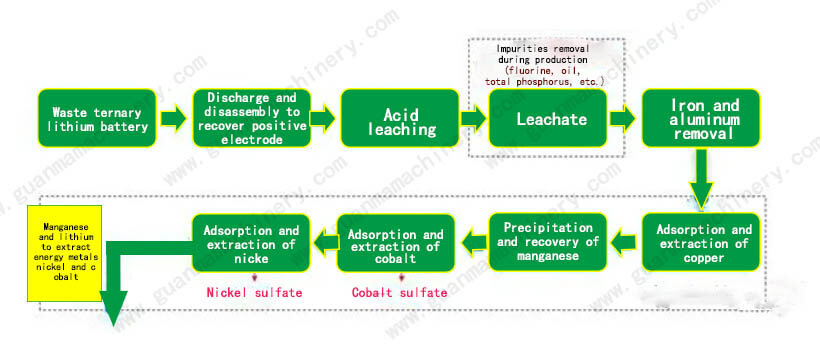

The lithium-ion battery black mass composition varies depending on the type of battery, but generally, it consists of metallic particles embedded in a carbon matrix. The complexity of the black mass necessitates advanced processing techniques to isolate and recover each metal effectively. Black mass processing involves several steps, including shredding, sieving, and hydrometallurgical treatment, to ensure the highest possible recovery rates.

The Role of Hydrometallurgy in Black Mass Recycling

A black mass hydrometallurgy machine is specifically designed to handle the chemically intensive process of separating and purifying metals from black mass. This process typically starts with leaching, where the black mass is dissolved in a solution to liberate the metals. Following leaching, the solution undergoes purification and concentration, leading to the extraction of lithium and other valuable metals.

Advantages of Using a Black Mass Hydrometallurgy Plant

Investing in a black mass plant equipped with a hydrometallurgy system offers numerous benefits. Firstly, it ensures a high degree of metal recovery, contributing to the circular economy. Secondly, the process is environmentally friendly compared to traditional pyrometallurgical methods, minimizing emissions and waste. Lastly, the lithium battery recycling black mass derived from this process is of superior quality, enhancing its market value.

GuanMa Machinery: A Leader in Black Mass Recycling Solutions

GuanMa Machinery stands at the forefront of innovation in the battery recycling sector. With a focus on developing efficient and eco-friendly black mass battery recycling solutions, GuanMa Machinery provides state-of-the-art black mass hydrometallurgy machines that are designed to optimize the recovery of lithium and other critical metals from black mass. Their commitment to sustainability and technological advancement makes them a trusted partner for businesses looking to adopt green practices in their operations.

As the world transitions towards greener energy solutions, the role of lithium extraction from black mass becomes more critical than ever. The black mass hydrometallurgy machine offered by GuanMa Machinery exemplifies the future of sustainable recycling, ensuring that valuable resources are reclaimed and reused in a responsible manner. Whether you’re a manufacturer seeking to integrate eco-friendly practices or a stakeholder interested in the latest recycling technologies, investing in black mass processing is a step towards a more sustainable future.