As the world transitions towards renewable energy and electric vehicles (EVs), the demand for lithium-ion batteries is skyrocketing. However, with the surge in battery production, there is an increasing need for efficient and sustainable recycling solutions. Establishing a lithium-ion battery recycling plant is not only a profitable venture but also a critical step in environmental conservation. In this article, we will explore the detailed cost structure and key considerations for setting up such a facility.

Understanding the Importance of Lithium-Ion Battery Recycling

Lithium-ion batteries are used in a wide range of applications, from smartphones and laptops to electric vehicles and energy storage systems. As these devices reach the end of their life, it is essential to recycle them to recover valuable materials like lithium, cobalt, nickel, and manganese. Recycling not only reduces the environmental impact of discarded batteries but also provides a secondary source of raw materials, reducing the reliance on mining and extraction.

Key Components and Costs Involved

1. Site Selection and Land Acquisition:

Choosing the right location for your recycling plant is crucial. The site should be easily accessible, have sufficient space, and comply with local zoning and environmental regulations. depending on the location and size of the land.

2. Equipment and Machinery:

The core of any lithium-ion battery recycling plant is its equipment. Here’s a breakdown of the essential machinery and their approximate costs:

Battery Disassembly System: This automated system is designed to safely and efficiently disassemble battery packs. depending on the processing capacity and configuration.

Crushing and Sorting Equipment: Once the batteries are disassembled, they need to be crushed and sorted.

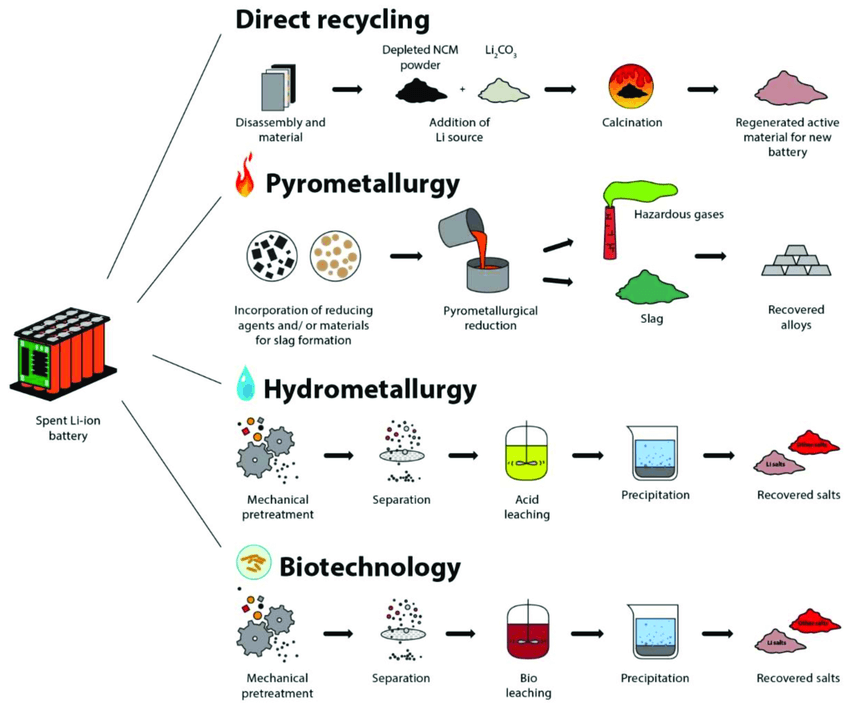

Hydrometallurgical or Pyrometallurgical Processing Units: These units are used to extract and purify the valuable metals.

Environmental Protection Facilities: To meet stringent environmental and safety standards, you will need absorption towers, bag filters, and wastewater treatment systems.

3. Raw Material and Supply Chain:

The cost of waste lithium-ion batteries as raw material varies by region. In countries with a high volume of EVs and electronic waste, such as India, the supply is relatively abundant, and the input cost may be lower. It is essential to establish a reliable supply chain to ensure a steady flow of raw materials.

4. Labor and Operational Costs:

Operating a recycling plant involves ongoing expenses, including labor, electricity, and transportation. The number of employees required depends on the plant’s capacity and automation level. For a medium-sized plant, you might need 10-20 workers, depending on the region.

5. Permits and Regulatory Compliance:

Obtaining the necessary permits and ensuring compliance with environmental and safety regulations is a critical step.

6. Initial Working Capital:

To cover initial operating expenses, such as raw material procurement, utilities, and other operational costs, you will need working capital. The amount required can vary, but a good estimate is around 20-30% of the total project cost.

The total cost of setting up a lithium-ion battery recycling plant can vary widely based on the factors mentioned above.

While the initial investment may seem substantial, the long-term financial and environmental benefits are significant. By recovering valuable materials, you can generate revenue through the sale of recycled metals. Additionally, government incentives and subsidies for green initiatives can help offset some of the costs. Moreover, contributing to a circular economy and reducing the environmental footprint of battery waste can enhance your company’s reputation and open up new business opportunities.

Setting up a lithium-ion battery recycling plant is a complex but rewarding endeavor. By carefully planning and considering all the key components and costs, you can create a sustainable and profitable business. If you are interested in learning more about the specific requirements and tailored solutions for your project, feel free to contact us.

For more information and to discuss your specific needs, please contact us or visit our website. We look forward to helping you build a successful and environmentally responsible lithium-ion battery recycling plant.