The global shift toward renewable energy has led to a surge in solar panel installations. But as older panels reach end-of-life, recycling them responsibly is critical. This raises a pressing question: How much does it cost to build a solar panel recycling plant? Whether you’re an investor, environmental entrepreneur, or industry stakeholder, understanding the financial commitment is key to entering this growing market.

Why Solar Panel Recycling Plant Cost Matters

Solar panel recycling is projected to become a $2.7 billion industry by 2030, driven by strict e-waste regulations and corporate sustainability goals. However, setting up a recycling facility requires significant upfront investment. Knowing the cost to build a solar panel recycling facility helps businesses plan budgets, secure funding, and identify profitable niches in the circular economy.

Key Components of Solar Panel Recycling Plant Costs

The total expense depends on scale, technology, and location. Below are the primary cost drivers:

1. Equipment and Technology (50–60% of Total Cost)

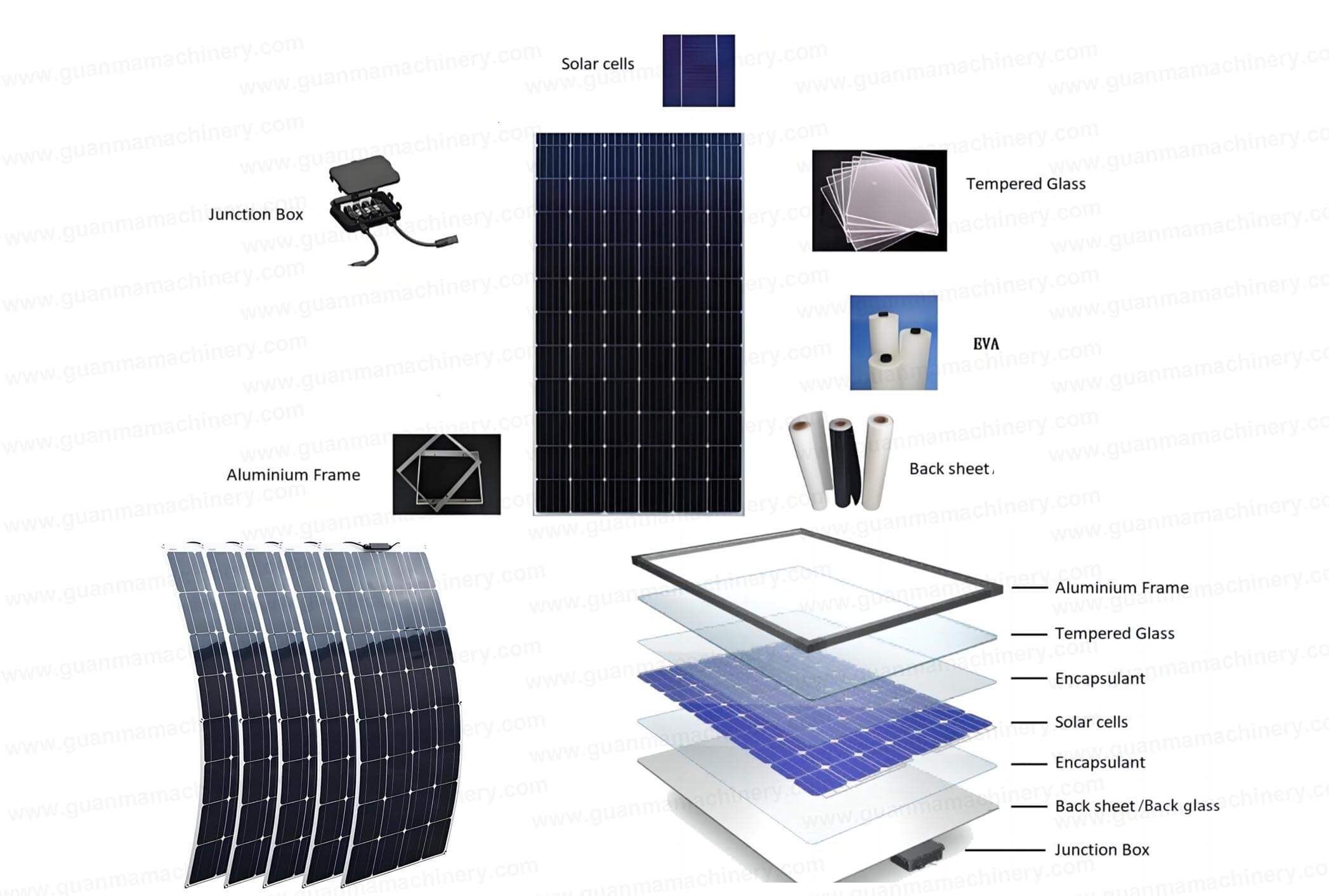

Solar panels contain glass, silicon, metals, and rare materials like silver. Specialized machinery is required to separate these components efficiently:

Mechanical Shredders: $200,000–$500,000(This data is for reference only).

Thermal Processing Units: $500,000–$1.2 million (This data is for reference only).

Chemical Separation Systems: $300,000–$800,000(This data is for reference only).

Sorting and Refining Equipment: $150,000–$400,000(This data is for reference only).

2. Facility Setup and Infrastructure (20–30%)

Land Acquisition or Leasing: Costs vary widely—$50,000/year in rural India vs. $500,000/year in Germany(This data is for reference only).

Building Construction/Renovation: $100–$300 per sq. meter(This data is for reference only).

Utility Connections (Power, Water): $50,000–$200,000(This data is for reference only).

3. Labor and Training (10–15%)

Skilled technicians and engineers are essential. Annual labor costs range from:

Asia: $150,000–$300,000(This data is for reference only).

Europe/North America: $500,000–$1 million(This data is for reference only).

4. Licensing and Compliance (5–10%)

Permits for hazardous waste handling, emissions, and safety protocols can add $50,000–$200,000, depending on local regulations(This data is for reference only).

Factors Affecting Solar Panel Recycling Plant Setup Expenses

Location: Labor, land, and energy costs differ regionally. For example, building in Southeast Asia may reduce expenses by 30% compared to the EU.

Capacity: A small plant processing 10,000 tons/year costs $2–5 million, while large-scale facilities (50,000+ tons) exceed $15 million(This data is for reference only).

Technology Choice: Pyrolysis and hydrometallurgy offer higher purity yields but require heavier investment than mechanical methods.

How to Reduce Solar Panel Recycling Plant Investment Costs

1. Government Grants and Subsidies: Many countries offer incentives for green ventures. The EU’s Circular Economy Action Plan funds up to 40% of recycling projects.

2. Modular Systems: Start small with scalable equipment to avoid overcapitalizing.

3. Partnerships: Collaborate with PV manufacturers or waste management firms to share infrastructure costs.

ROI: Is a Solar Panel Recycling Plant Profitable?

Despite high initial costs, recycling plants can achieve 15–25% profit margins by:

Selling recovered materials (e.g., silicon, aluminum, glass).

Charging recycling fees ($20–$50 per panel)(This data is for reference only).

Leveraging carbon credit programs.

Balancing Cost and Sustainability

The solar panel recycling plant cost is a complex equation, but with strategic planning, it’s a viable and impactful investment. As solar waste volumes grow—estimated at 60 million tons by 2050—recycling plants will play a pivotal role in achieving a zero-waste future.

By analyzing location-specific expenses, adopting efficient technologies, and tapping into subsidies, businesses can turn solar panel recycling into a profitable, environmentally transformative venture.