Hydrometallurgical Battery Recycling Plant Quotation—are you exploring the most efficient and eco-friendly ways to recycle lithium-ion batteries (LIBs)? If so, you’re on the right track. With the increasing demand for black mass recycling, hydrometallurgical processes have emerged as a leading solution. This article delves into the benefits of choosing a hydrometallurgical battery recycling plant, including the key steps involved, the machinery required, and why it might be a better choice over pyrometallurgy.

What Is Hydrometallurgy in Battery Recycling?

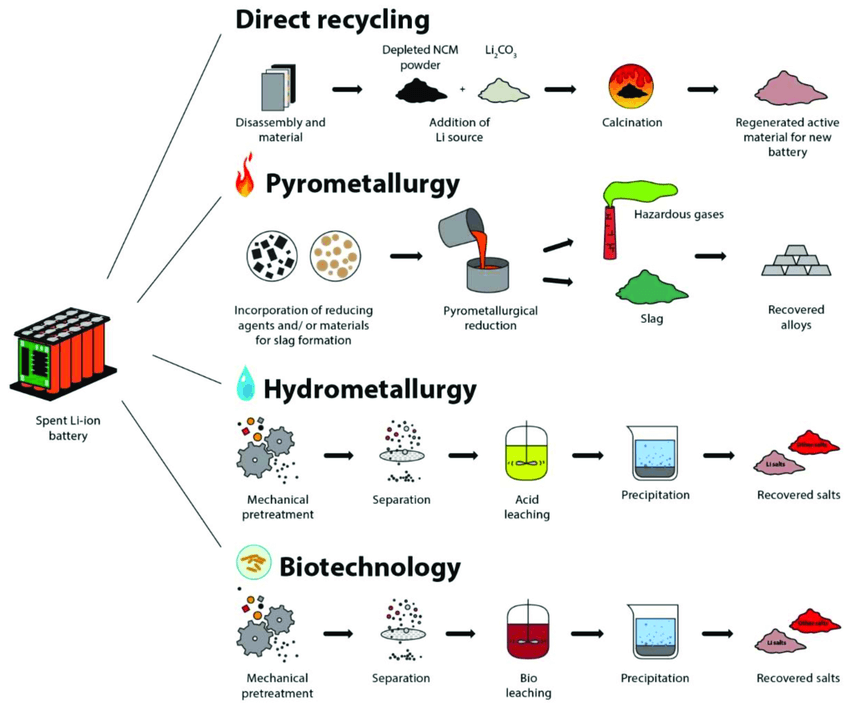

Hydrometallurgy involves using aqueous solutions to extract valuable metals from spent batteries. This process is particularly effective for recovering metals like lithium, cobalt, and nickel from the black mass generated during initial shredding and sorting stages.

How Are LIBs Recycled Using Hydrometallurgy?

1. Pre-treatment: Batteries undergo mechanical processing, including shredding and sieving, to produce black mass.

2. Leaching: The black mass is treated with a leaching agent, typically an acid, to dissolve metals.

3. Extraction: Precious metals are selectively extracted from the leachate using solvent extraction or precipitation techniques.

4. Purification and Recovery: Metals are purified and recovered through electro-winning or other methods.

Is Hydrometallurgy Battery Recycling Better Than Pyrometallurgy?

Compared to pyrometallurgy, which uses high temperatures to recover metals, hydrometallurgy offers several advantages:

Higher Recovery Rates: It can achieve higher purity and recovery rates for critical metals.

Lower Environmental Impact: Lower energy consumption and reduced emissions make it more sustainable.

Flexibility: It can be adapted to different types of batteries and changing technologies.

Battery Recycling Process Machinery

To establish a hydrometallurgical battery recycling plant, you’ll need specialized machinery, including shredders, leaching tanks, filtration systems, and purification equipment. These machines are designed to optimize the recycling process, ensuring maximum metal recovery while minimizing waste.

Choosing a hydrometallurgical battery recycling plant is a strategic move towards a greener future. By leveraging advanced machinery and processes, you can efficiently recycle LIBs, recover valuable metals, and contribute to sustainable practices. Contact us today for a detailed quotation tailored to your specific needs and scale of operation.