In the realm of lithium-ion (Li-ion) battery recycling, hydrometallurgy stands out as a highly effective method for separating and recovering valuable metals from spent batteries. As the demand for Li-ion batteries continues to soar, the need for sustainable and efficient recycling processes becomes increasingly critical. This article delves into the intricacies of the hydrometallurgical battery recycling process and highlights GuanMa Machinery as a leading hydrometallurgy line for black mass separation manufacturer.

What is Hydrometallurgy in Battery Recycling?

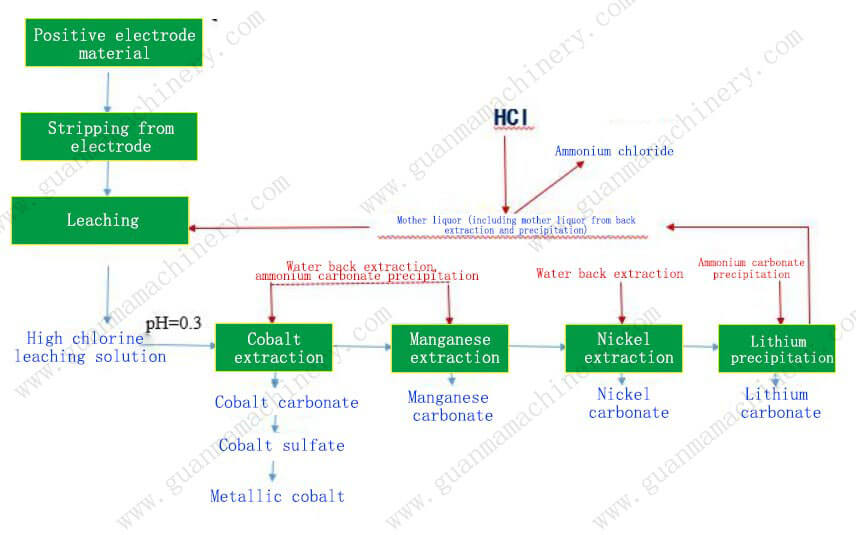

Hydrometallurgy is a chemical-based process used to extract metals from ores and other solid materials, including lithium-ion battery waste. In the context of lithium ion battery recycling, hydrometallurgy involves the use of aqueous solutions to dissolve metal compounds, allowing for the selective separation and recovery of valuable metals such as lithium, cobalt, nickel, and manganese. The end product of this process is often referred to as “black mass,” which contains a mixture of valuable metals.

Lithium Ion Battery Recycling: Black Mass and Beyond

The hydrometallurgical process begins with the mechanical preprocessing of spent batteries, which typically includes discharging, shredding, and sorting. Once the batteries are reduced to smaller particles, the black mass is separated, containing the valuable metal compounds. This is followed by leaching, where the black mass is dissolved in a chemical solution to separate the metals.

GuanMa Machinery: A Trusted Manufacturer

GuanMa Machinery is renowned for its expertise in developing and manufacturing hydrometallurgy lines specifically designed for black mass separation. Their systems are engineered to maximize efficiency and recovery rates while ensuring minimal environmental impact. By partnering with GuanMa Machinery, you gain access to:

Cutting-edge Technology: Advanced machinery and equipment optimized for the hydrometallurgical process.

Customized Solutions: Tailored systems designed to meet the unique requirements of your recycling operation.

End-to-End Support: Comprehensive services ranging from system design and installation to maintenance and technical support.

Advantages of Hydrometallurgical Battery Recycling Process

The hydrometallurgical process offers several key advantages over alternative recycling methods:

1. High Recovery Rates: The process is capable of achieving high recovery rates of valuable metals, making it economically viable.

2. Environmental Benefits: Hydrometallurgy reduces the environmental footprint by minimizing waste and emissions compared to traditional smelting techniques.

3. Flexibility: The process can be adapted to handle different types and sizes of lithium-ion batteries, making it versatile and scalable.

As the world shifts towards more sustainable practices, the importance of lithium ion battery recycling hydrometallurgy cannot be overstated. By choosing GuanMa Machinery as your hydrometallurgy line for black mass separation manufacturer, you are investing in a future where valuable resources are conserved, and environmental impact is minimized.