Are you looking to establish a lead acid battery recycling plant in India? With the growing demand for sustainable and eco-friendly solutions, setting up a used lead acid battery recycling plant can be a highly profitable and environmentally responsible venture. This article will guide you through the key aspects of starting and operating a lead acid battery recycling plant in India, including the necessary equipment, costs, and benefits.

Why Invest in a Lead Acid Battery Recycling Plant in India?

India is one of the world’s largest markets for lead-acid batteries, driven by the automotive industry, UPS systems, and other industrial applications. As the number of used batteries increases, so does the need for effective and sustainable recycling solutions. By investing in a lead acid battery recycling plant in India, you not only contribute to environmental sustainability but also tap into a lucrative market with significant growth potential.

Environmental and Economic Benefits

Reduced Environmental Impact: Proper recycling of lead-acid batteries prevents the release of toxic materials into the environment, reducing pollution and health risks.

Resource Recovery: Recycling allows for the recovery of valuable materials such as lead, plastic, and acid, which can be reused or sold, creating additional revenue streams.

Economic Growth: Establishing a lead acid battery recycling plant can create local jobs and support the circular economy, contributing to the overall economic development of the region.

Key Components of a Lead Acid Battery Recycling Plant

Lead Acid Battery Recycling Machine

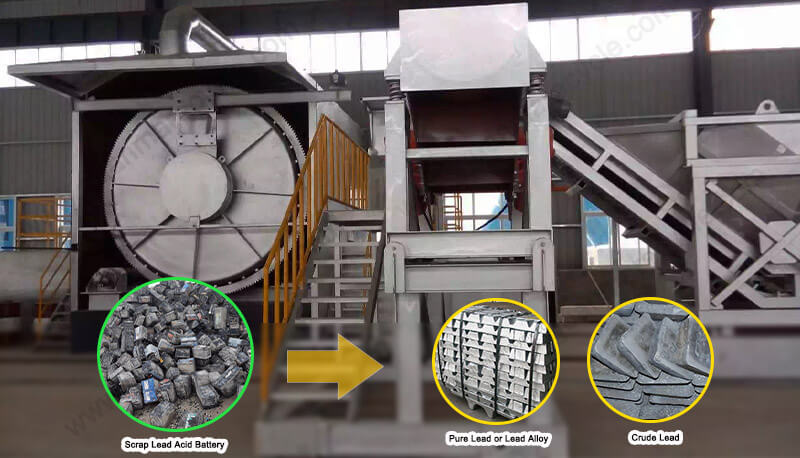

The heart of any lead acid battery recycling plant is the lead acid battery recycling machine. These machines are designed to efficiently break down and process used batteries, separating the components for further refinement. Key features include:

Battery Breaking System: This system safely breaks open the batteries and separates the lead, plastic, and electrolyte.

Lead Smelting Furnace: The separated lead is smelted and refined to produce high-quality lead ingots.

Acid Neutralization System: The sulfuric acid from the batteries is neutralized and treated to ensure safe disposal or reuse.

Plastic Separation and Washing System: The plastic casings are cleaned and separated for recycling.

Cost Considerations for a Lead Recycling Plant

The lead recycling plant cost can vary depending on several factors, including the scale of the operation, the type of equipment, and the location. Here are some key cost considerations:

Initial Investment: The cost of purchasing and installing the lead acid battery recycling machine and other necessary equipment.

Operational Costs: Ongoing expenses such as labor, energy, maintenance, and raw material costs.

Regulatory Compliance: Costs associated with obtaining necessary permits and adhering to environmental and safety regulations.

Training and Staffing: Expenses related to training personnel and hiring a skilled workforce.

Steps to Establish a Lead Acid Battery Recycling Plant in India

1. Market Research and Feasibility Study

Conduct thorough market research to understand the demand for recycled lead and other materials.

Perform a feasibility study to evaluate the financial viability and potential return on investment.

2. Obtain Permits and Licenses

Secure the necessary permits and licenses from local and national authorities.

Ensure compliance with environmental and safety regulations.

3. Site Selection and Infrastructure Development

Choose a suitable location with access to transportation and utilities.

Develop the infrastructure, including the construction of the plant and installation of equipment.

4. Procure Equipment and Train Staff

Purchase and install high-quality lead acid battery recycling machines and other necessary equipment.

Train your staff on the proper operation and maintenance of the equipment.

5. Launch and Operate

Begin operations and focus on optimizing the production process.

Implement quality control measures to ensure the production of high-quality recycled materials.

Conclusion

Establishing a lead acid battery recycling plant in India is a strategic and sustainable business opportunity. By investing in advanced lead acid battery recycling machines and adhering to best practices, you can create a successful and environmentally responsible enterprise. If you are ready to take the next step, contact us today to learn more about our comprehensive solutions and support services.