The growing demand for electric vehicles (EVs) has led to a rise in the use of lithium-ion batteries. As these batteries reach their end-of-life, the need for efficient recycling methods has never been more critical. The LFP (Lithium Iron Phosphate) black mass processing plant plays a pivotal role in this process, providing a sustainable solution for extracting valuable materials from spent batteries.

What is LFP Black Mass?

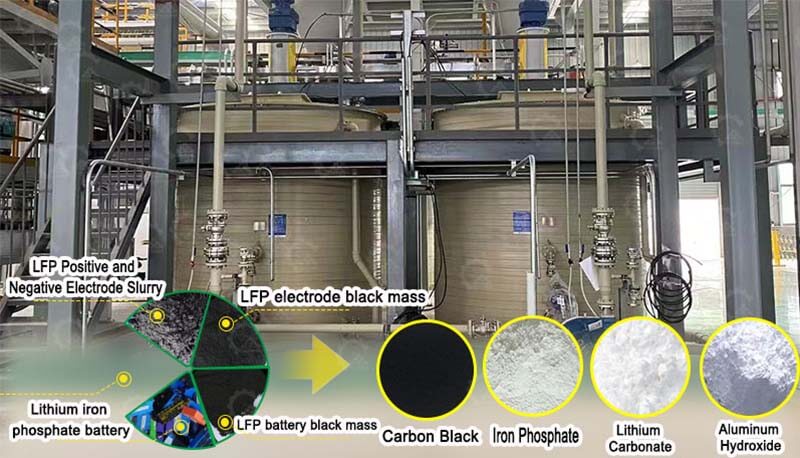

LFP black mass is the material derived from lithium-ion batteries during the recycling process. It contains valuable components like lithium, iron, phosphate, and other metals, which can be reused in the production of new batteries. By efficiently processing this black mass, the LFP black mass processing plant helps reduce the environmental impact of battery disposal and supports the growing demand for raw materials in the green energy sector.

Why Choose an LFP Black Mass Processing Plant?

1. Sustainability: Recycling LFP black mass is crucial for minimizing waste and reducing the need for mining raw materials. This supports a circular economy and ensures a more sustainable supply of battery materials.

2. Cost-Effective: By recovering valuable metals, the LFP processing plant can help lower production costs for new batteries. This is especially important as the world transitions to electric vehicles and renewable energy storage solutions.

3. Cutting-Edge Technology: Modern LFP black mass processing plants use advanced technologies to optimize extraction rates and enhance the purity of recovered materials. This ensures high-quality raw materials for new battery manufacturing.

4. Environmentally Friendly: Battery recycling reduces harmful waste and minimizes environmental pollution. With more LFP black mass processing machines, the energy and material costs associated with battery production decrease, contributing to a cleaner environment.

How Does the LFP Black Mass Processing Plant Work?

The LFP black mass processing machine uses a multi-step process to extract valuable materials from spent batteries:

1. Pre-Treatment: The spent lithium-ion batteries are first shredded and processed to separate the different components.

2. Pyrometallurgical or Hydrometallurgical Extraction: Depending on the plant, either pyrometallurgical (heat-based) or hydrometallurgical (chemical-based) methods are used to extract metals like lithium, iron, and phosphate from the black mass.

3. Purification and Refining: The extracted materials are purified and refined to meet industry standards for battery production.

4. Reuse and Recycling: The recovered materials are then used to manufacture new lithium-ion batteries, ensuring that the supply chain remains sustainable.

The Future of LFP Black Mass Processing

As global demand for electric vehicles and renewable energy systems increases, the importance of efficient battery recycling cannot be overstated. The LFP black mass processing plant is at the forefront of this transformation, enabling a future where battery materials are reused and recycled in a sustainable loop.

The future of battery recycling lies in advancing the technology used in LFP black mass processing plants. With continuous improvements in efficiency and environmental impact, these plants are set to play a major role in supporting the green energy revolution.