Currently, lithium battery recycling, as a post-cycle industry for new energy vehicles, is entering a phase of accelerated development. Driven by policies promoting the circular and regenerative industries, the recycling and comprehensive utilization of retired power batteries, which are both environmentally friendly and economically viable, have a broad prospect for development.

Since 2015, when China’s new energy vehicle (NEV) production began to surge, NEV sales have been on a steady rise. The early generations of power lithium-ion batteries have gradually started to reach their end-of-life stage.

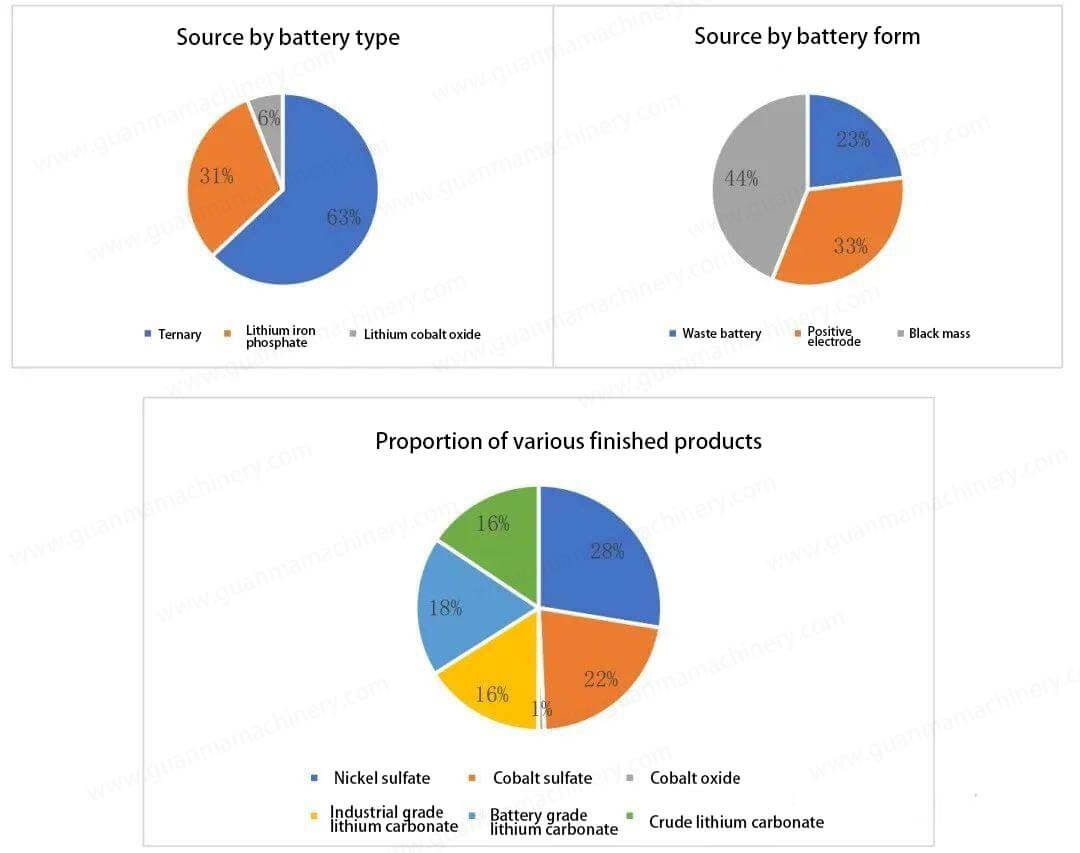

Domestic waste lithium battery volumes are substantial, becoming an important resource recovery channel. According to research and statistics, in 2022, the total amount of recycled waste lithium batteries in China exceeded 300,000 tons, including scrapped batteries from society, positive electrode sheets, and black mass, as well as scraps and defective products from battery manufacturing. In terms of battery types, ternary waste accounted for 188,692 tons or 63%; lithium iron phosphate waste was 94,551 tons or 31%; and lithium cobalt oxide waste made up 17,015 tons or 6%.

From the perspective of battery form, there were 68,141 tons of spent batteries, accounting for 23%; 99,024 tons of positive electrode sheets, representing 33%; and 133,093 tons of black powder, making up 44%.

In terms of product output, the recycling process yielded 32,380 tons of nickel sulfate, 25,418 tons of cobalt sulfate, 977 tons of cobalt oxide, 18,708 tons of industrial-grade lithium carbonate, 21,560 tons of battery-grade lithium carbonate, and 18,323 tons of crude lithium carbonate.

Industry Drivers

1) Environmental Mandates and Economic Value

Power batteries have a complex composition with multiple components such as metals, non-metals, solids, and liquids coexisting. Metals like cobalt, nickel, lithium, manganese, iron, and copper, if not properly recycled, can undergo acid reactions, transforming into ionic states that cause heavy metal pollution. Graphite powder from the negative electrodes, due to its fine particle size, can easily lead to dust pollution. The electrolyte solutes and their conversion products, along with solvents and their decomposition and hydrolysis products, mostly contain toxic and harmful substances. The recycling of power batteries is an essential part of environmental protection. Moreover, power lithium-ion batteries contain a large amount of valuable rare earth elements and non-ferrous metals, such as cobalt, lithium, nickel, copper, and aluminum, with higher metal content than ores. Recycling these non-renewable resources from used batteries has significant economic value.

2) Stabilizing Supply Chain Demand

Nickel, cobalt, and lithium resources are scarce, and in recent years, the price of lithium carbonate has experienced dramatic fluctuations, including sharp rises and falls. The volatility of raw material prices greatly impacts the stability of the supply chain for battery manufacturers and automakers, which is detrimental to the development of NEV brands. In the long run, compared to direct mining, material recycling provides a faster way to utilize resources. As an important means of resource supplementation, it contributes to the stabilization of the NEV supply chain.

3) Policy Promotion

In recent years, a series of policies and standards concerning the recycling and reuse of power batteries have been introduced, covering aspects such as design, production, disassembly, collection, recycling, transportation, storage, cascading use, and regeneration of automotive power batteries. With the gradual improvement and perfection of policies and standards, it is expected that the scale of the recycling industry will expand, and the level of technology and standardization will also be further enhanced.