In the age of rapid technological advancement and increasing environmental consciousness, the establishment of a lithium ion battery pack recycling plant emerges as a pivotal response to the escalating challenges posed by lithium-ion waste. This article will delve into the intricacies of setting up and operating a lithium ion recycling plant, emphasizing its role in managing swollen lithium ion battery disposal, while also addressing common concerns such as battery recycling plant cost and the lithium ion battery recycling process.

With the proliferation of lithium-ion batteries in electronic devices, electric vehicles, and energy storage systems, the need for responsible disposal lithium batteries has never been greater. Swollen lithium ion batteries, in particular, pose safety risks due to potential leaks and fires, necessitating specialized handling. A lithium ion battery pack recycling plant not only mitigates these risks but also recovers valuable materials, contributing to a circular economy.

Understanding the Lithium Ion Battery Recycling Process

The lithium ion battery recycling process involves several stages aimed at maximizing material recovery and ensuring safe disposal:

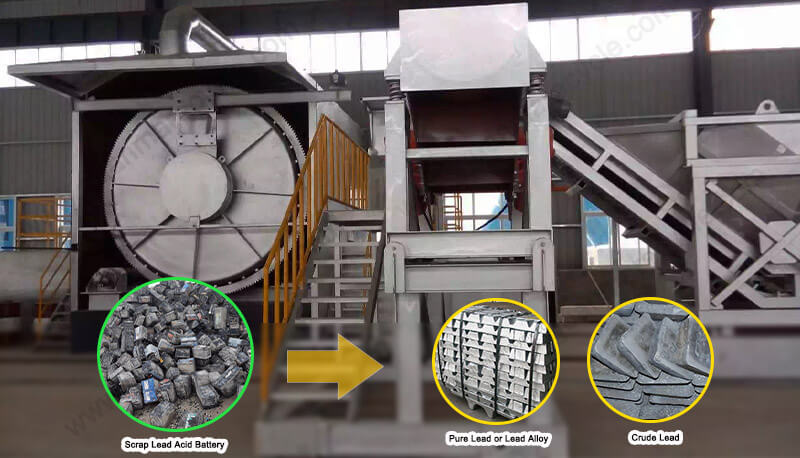

1. Collection and Preprocessing: Batteries are collected and transported to the recycling facility. Preprocessing includes discharging and shredding to prepare the batteries for further processing.

2. Mechanical Separation: Components like plastics, metals, and electrolytes are mechanically separated. This stage also involves the isolation of the black mass, a mixture rich in valuable metals.

3. Hydrometallurgical Processing: The black mass undergoes leaching in acidic or alkaline solutions to dissolve metals. This allows for the selective recovery of lithium, cobalt, nickel, and other metals.

4. Refining and Recovery: Recovered metals are refined to meet purity standards before being reintroduced into the manufacturing supply chain.

The cost of establishing a battery recycling plant varies depending on factors such as scale, technology, and location. While initial investment may seem substantial, the long-term benefits, including material recovery revenues and environmental compliance savings, make it a financially viable endeavor. Additionally, governments and industry bodies often offer incentives and grants to promote recycling initiatives, helping to offset some of the upfront costs.

Why Invest in a Lithium-ion Battery Pack Recycling Plant?

Investing in a lithium-ion battery pack recycling plant is not merely a response to environmental necessity; it represents a strategic move toward sustainable business practices.

The establishment of a lithium-ion battery pack recycling plant presents a compelling opportunity for businesses to contribute to environmental sustainability while tapping into the economic potential of recycled materials. By understanding the lithium ion battery recycling process, addressing concerns such as battery recycling plant cost, and embracing the benefits of responsible lithium-ion waste management, companies can pave the way for a greener future.

If you are contemplating the setup of a lithium-ion battery recycling plant or wish to learn more about how to integrate sustainable practices into your business model, feel free to reach out.