The lithium ion battery recycling hydrometallurgy process is emerging as a pivotal solution in addressing the environmental challenges posed by battery waste. As the demand for electric vehicles and renewable energy storage grows, the recycling of lithium-ion batteries has become essential. This innovative approach utilizes aqueous chemistry to recover valuable metals like lithium, cobalt, and nickel, minimizing the ecological footprint of battery production and disposal.

Introduction to Hydrometallurgical Process

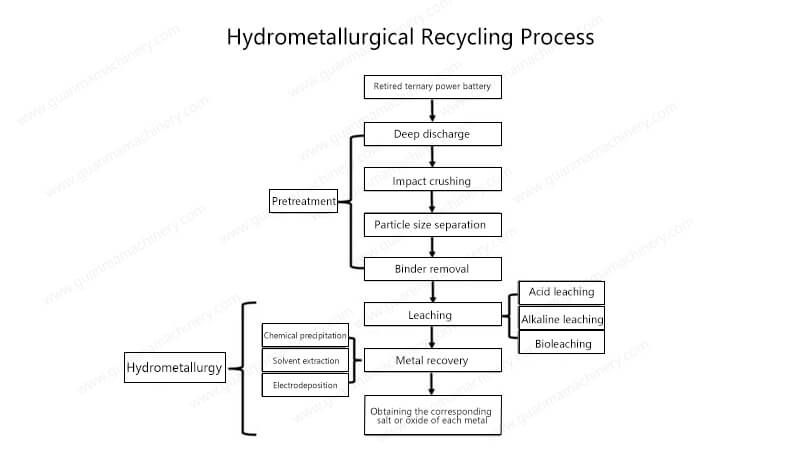

The hydrometallurgical process begins with the mechanical pre-treatment of spent batteries, which involves crushing and shredding to facilitate the liberation of valuable components. This is followed by leaching, where chemical agents such as sulfuric acid or hydrochloric acid are used to dissolve metals from the battery materials. The resultant solution is then subjected to selective precipitation and solvent extraction, enabling the separation of specific metals with high purity.

Advantages of hydrometallurgical process

One of the ultimate advantages of hydrometallurgy over traditional pyrometallurgical methods is its lower energy consumption and reduced greenhouse gas emissions. Additionally, hydrometallurgy can efficiently process complex battery chemistries, making it a versatile choice for diverse battery types. As research advances, new leaching agents and process optimizations are continually being developed, improving recovery rates and reducing costs.

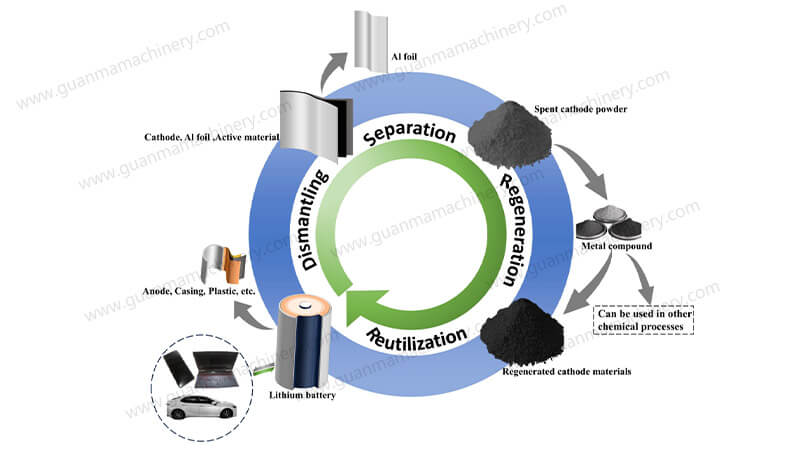

Hydrometallurgical processes comply with the principles of circular economy

Moreover, the hydrometallurgical process aligns with circular economy principles by promoting resource recovery and minimizing waste. Companies and researchers are increasingly collaborating to enhance this technology, aiming for commercial viability and widespread adoption. By investing in hydrometallurgy, industries can not only meet regulatory requirements but also contribute to a sustainable future.

In conclusion, the lithium ion battery recycling hydrometallurgy process represents a crucial step towards sustainable resource management. As innovations unfold, this method could ultimately reshape the landscape of battery recycling, ensuring that valuable materials are reused and that the environmental impact of battery disposal is significantly reduced. Embracing this technology is not just an option; it’s a necessity for a greener tomorrow.