As global reliance on lithium-ion batteries grows, so does the urgency for sustainable recycling solutions. India, with its burgeoning electric vehicle (EV) market, presents a promising landscape for lithium ion battery recycling plant investments. Let’s delve into the factors shaping the lithium ion battery recycling plant cost in India.

Setting Up a Lithium Ion Battery Recycling Plant in India Initial Investment Breakdown

Starting a lithium ion battery recycling plant in India involves several significant costs:

Land and Infrastructure: The price of land varies widely across India, influenced by location, accessibility, and proximity to urban centers. Building a facility to house recycling operations adds to this cost.

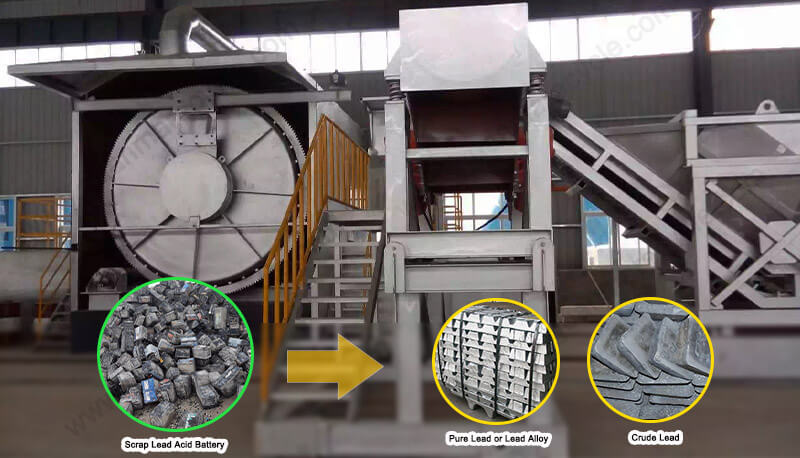

Equipment and Technology: Advanced machinery for shredding, sorting, and chemical processing is essential. Hydrometallurgical and pyrometallurgical systems for extracting lithium, cobalt, and nickel are costly but critical.

Regulatory Compliance: Meeting environmental standards and obtaining necessary permits adds to the initial expenditure.

Human Resources: Skilled labor is required for plant operations and maintenance.

Working Capital: Funds for day-to-day operations, including raw material procurement (spent batteries) and utilities.

Ongoing Expenses

After the initial setup, ongoing expenses include:

Labor: Salaries for technicians, engineers, and administrative staff.

Utilities: Electricity, water, and gas consumption.

Maintenance: Regular upkeep of machinery to ensure optimal performance.

Raw Material: The cost of spent lithium-ion batteries, which can fluctuate based on market demand.

Environmental Monitoring: Ongoing monitoring to ensure compliance with environmental regulations.

Government Incentives and Support

The Indian government encourages green initiatives through subsidies, tax breaks, and grants. Investors should explore these opportunities to mitigate some of the lithium ion battery recycling plant cost in India.

Market Potential

With the Indian EV market forecasted to grow exponentially, the demand for lithium-ion battery recycling services will increase. Recycled materials like lithium, cobalt, and nickel are valuable commodities, making the recycling business not only environmentally responsible but also economically viable.

Understanding the lithium ion battery recycling plant cost in India is crucial for prospective investors. While initial costs can be substantial, the long-term prospects of this sector are promising, driven by environmental necessity and economic opportunity. Investors must weigh these factors against potential returns and consider the evolving landscape of government support and market demand.