This Continuous Carbonization Pyrolysis Machine is a device that transforms organics into carbon, classified into three categories based on feedstock usage:

1. Biomass Materials (suitable for processing wood chips, coconut shells, palm kernels, peanut shells, rice husks, crop stalks, bamboo, peach stone shells, sawdust, and other biomass wastes).

2. Solid Waste Materials (designed for handling aluminum cans, lithium battery, aluminum capacitors, solar panel, ACP, black mass, enameled wires, and other e-wastes).

3. Sludge Materials (intended for processing municipal sludge, lndustrial sludge, dyeing sludge, anode sludge, etc).

Raw Material

Biomass Raw Material

Biomass Materials are used for processing wood, coconut shells, palm kernel shell, sawdust, rice husks, wood pellets, plant straw, bamboo, peanut shells, peach stone shells, and other biomass wastes.

Solid Waste Raw Material

Solid Waste Materials are utilized for handling aluminum cans, lithium-ion batteries, aluminum capacitors, solar PV panels, aluminum composite boards, black mass, enameled wires, and other electronic wastes.

Sludge Raw Material

Sludge Materials are aimed at processing urban sludge, industrial sludge, printing and dyeing sludge, anode mud, and similar substances.

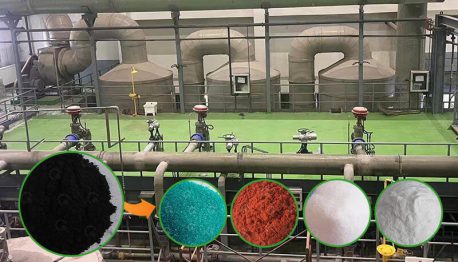

Final Product

Final products yielded after carbonization include palm shell carbon, rice husk carbon, straw carbon, tar, wood carbon, wood vinegar, charcoal, coconut chell carbon, combustible gas.

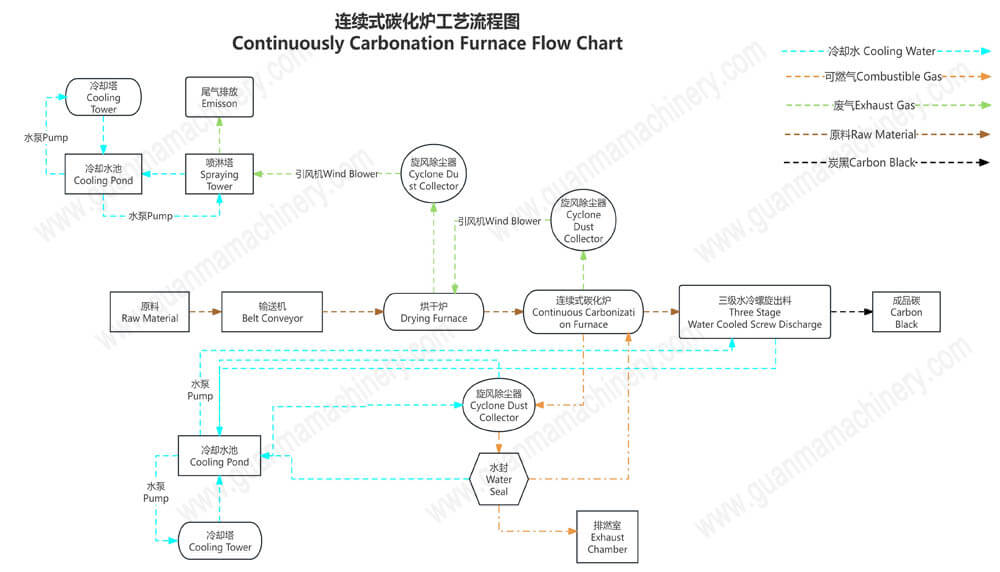

Flow Chart

Technical Parameter

Continuous Carbonization Pyrolysis Equipment Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity | Size of Main Reactor(Diameter*L) | RPM | Size(㎡) |

| CF-1000 | 500-600kg/h | φ1000*10500mm | 4-10r/min | 240㎡ |

| CF-1200 | 600-800kg/h | φ1200*10500mm | 4-10r/min | 350㎡ |

| CF-1200-II | 800-1000kg/h | φ1200*10500mm | 4-10r/min | 350㎡ |

| CF-1500 | 1000-1200kg/h | φ1500*10500mm | 4-10r/min | 400㎡ |

| CF-1500-II | 1200-1500kg/h | φ1500*10500mm | 4-10r/min | 400㎡ |

| CF-1800 | 1500-2000kg/h | φ1800*10500mm | 4-10r/min | 500㎡ |

| CF-1800-II | 2000-2200kg/h | φ1800*10500mm | 4-10r/min | 500㎡ |

| This table is for reference only, please refer to the final quotation table. | ||||

Product Advantages

1. The continuous charcoal machine operates continuously, feeding raw materials from the inlet and discharging them from the outlet, achieving high production efficiency and substantial output.

2. The continuous carbonizer integrates functions such as coke gasification, smart control, automatic collection of tar and wood vinegar, and synchronized recycling of combustible gases.

3. The equipment design is more compact, reducing the space occupied by the machinery, facilitating transportation, and cutting down on shipping costs.

4. The environmentally friendly carbonization furnace produces combustible gases during carbonization that can be recycled back into the furnace for burning, resulting in no smoke, odor, or pollution, showcasing environmental friendliness and energy conservation with a carbonization rate exceeding 99%.

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)