The refining principle of copper electrolysis machine: using the potential difference between copper and impurities, direct current is passed, the crude copper on the anode plate is electrochemically dissolved, and the copper ions near the cathode are electrochemically precipitated on the cathode. Precious metals and some impurities enter the anode mud, and most impurities are retained in the electrolyte in the form of ions, thus achieving the separation of copper and impurities, and the crude copper is purified into cathode copper (refining process): Cu (crude copper) -→ Cu’ (cathode copper)

Raw Materia

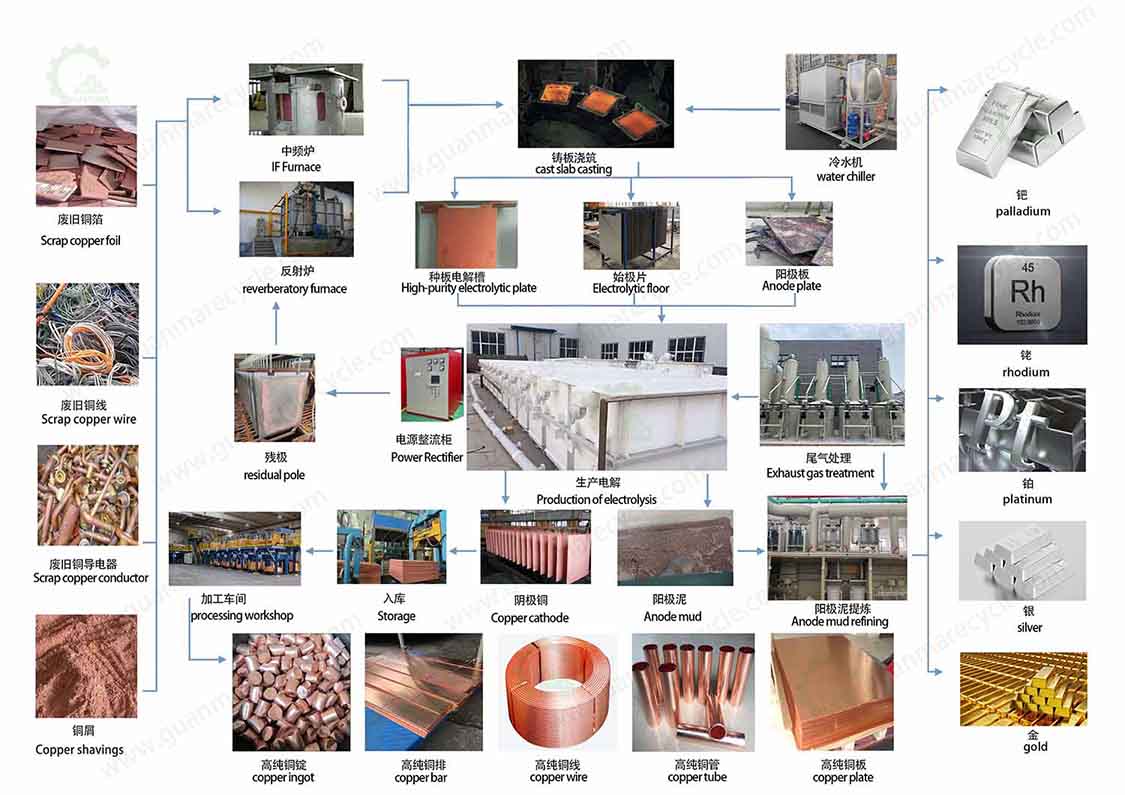

Copper electrolysis machine can process raw materia: scrap copper wire, scrap copper foil, scrap copper conductor, copper shavings, ect.

Final Product

The final product from the copper electrolysis machine is high purity copper, normal is 99.9%, if you have higher require, also can do 99.99% or 99.9999%

Flow Chart

In the electrolysis, Cu2+ obtains the the electron and turns into pure copper at the cathode. At the same time, gold, silver, palladium and the platinum remains in the anode mud. the anode mud be washed, undertake reducing smelting and oxidation smelting in frequency furnace, then we can get the precious metal alloy block. Then have it water broken, and then through the precious metal to make liquid extraction separation and refining a variety of precious metals.

Product Advantages

In the workshop, all place producing exhausting gas must be set up tail gas absorption device with the ozone, all places producing tail liquid must establish fluid diversion device, the tail liquid will be lead to the waste water treatment plant and be discharged or reused after meet the standard.

1. After processing the tail liquid can be consistent with national environmental requirements.

2. The recovery rate of gold, silver, palladium and platinum can be above 99% and the purity of precious metals can be above 99%.

3. Automatic controlling, compared with other processes, labor costs can be reduced by 90%.

4. The exhaust gas treatment system can produce useful chemicals, creating added value.

5. Advanced technology make the electrolytic cycle much shorter.

6. The use of automatic control system for exhaust emissions,, no secondary pollution.

Technical Parameter

Copper Electrolytic Refining Equipment Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Mixed Metal Powder | Energy Consumption(KWH) | Electrolytic Cycle(Anode/Cathode) | Copper Capacity | Copper Purity |

| CER-500 | 500kg/day | 280 | 15days/48h | 370 | 99.9% |

| CER-1000 | 1000kg/day | 570 | 15days/48h | 750 | 99.9% |

| CER-2000 | 2000kg/day | 1130 | 15days/48h | 1500 | 99.9% |

| CER-5000 | 5000kg/day | 2850 | 15days/48h | 3750 | 99.9% |

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)