The waste circuit board recycling plant recover precious metals efficiently from e -scrap discharged by electronic manufacturers domestically and abroad. The e-scrap includes waste PCB, Leftover bits and pieces,Electronic components, electronic equipment, etc.

Raw Materia

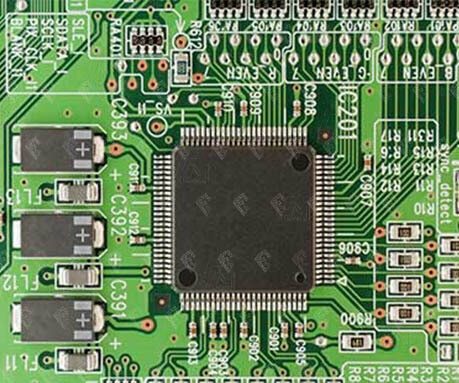

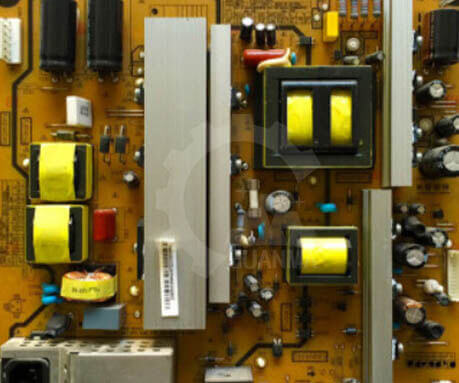

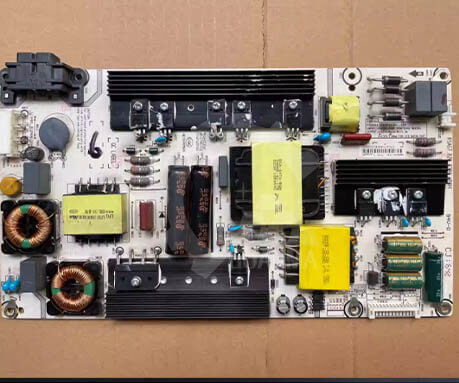

E Waste Circuit Board Recycling Plant can process: Waste printed circuit board with or without electronic components;CCL( copper-clad plate), PCB leftover material; Scrap circuit boards, such as computer board, mobile phone board, TV board, etc.

waste circuit boards mainly comes from all kinds of scrap electric appliances, mainly including green board and yellow board. Green board is dismantled from waste televisions, computers, communications equipment, with high vafue;yellow palte mainly from the tape recorder, audio equipment, washing machines, air conditioning and dismantling, with low value.

Final Product

Final Products: Metal powder, Resin powder, gold, silver, palladium, platinum.

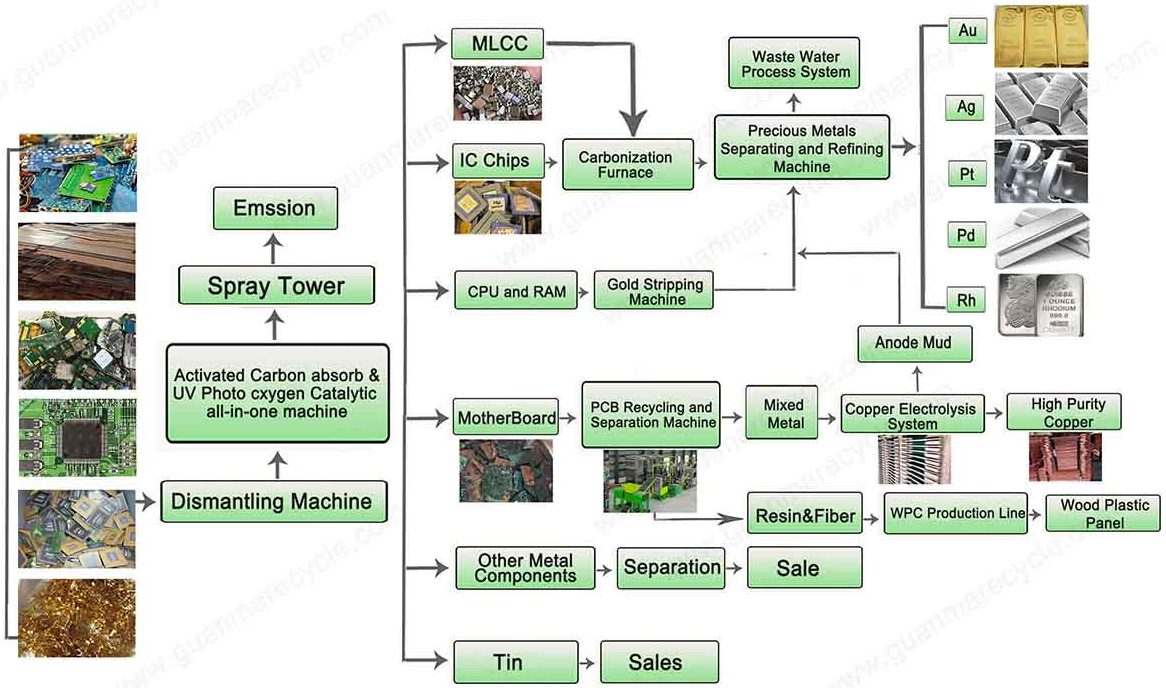

Flow Chart

E Waste Circuit Board Recycling Plant is a kind machine which is specially used for processing E-waste products, and it is crushing, separation, and recycling. It is made of different units to make sure process scrap PCB, the main process of machine is like this:

Preprocess: Separation and Dismantling

It is better to separate different kinds of PCB according to different applications. And then will use different PCB dismantling machine to dismantle all kind of components.

Crushing and Separation line:

We put the PCB motherboard on the belt conveyor, they will go into the double shaft shredder. After shredding, raw material will get 5-10cm.

Then raw material will go into hammer crusher, then raw material will be 8-10mm.

In order to get higher separation rate, will use grinder to do further process, after grinder, will get raw material 20-24mesh.

Then will do the separation part, the air separator will do the first separation. According to the different forces, the metal and resin&fiber are separated. In order to get higher separation, will use electrostatic separator to do further separation. The metal and resin&fiber will have different charging properties, then will do the separation. At last the separation rate can get more than 99%.

During machine working, machine has pulse dust collectors to collect dust. The whole dust collect rate can get more than 99%.

The Scrap PCB Crushing and Separation Machine effectively handles large quantities of discarded electronic products, achieving efficient recycling of resources and reducing environmental pollution. With the widespread use and rapid upgrading of electronic products, this equipment plays an important role and has promising prospects in the field of environmental protection.

Product Advantages

1. Reasonable layout, stable performance, lower noise.

2. The recycling plant of waste circurt board use two stage crushing, which can make sure the capacity up to 800kg per hour.

3. The whole process line adopts negative pressure feeding way to transfer raw material to reduce dust.

4. After air separator and electrostatic separator process, the whole separation rate can reach about 99%.

5. Machine use PLC control, which is easy to operate.

6. Machine use physical way to process waste circurt board, totally environmental.

Technical Parameter

E Waste Circuit Board Recycling Plant Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity | Power | Size(Length*Width*Height) |

| PCB-300 | 200-300kg/h | 102KW | 20000*5000*5000mm |

| PCB-500 | 400-500kg/h | 134KW | 25000*6000*5000mm |

| PCB-800 | 800-1000kg/h | 194KW | 30000*6000*5000mm |

| PCB-1000 | 800-1000kg/h | 238KW | 35000*8000*5000mm |

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)