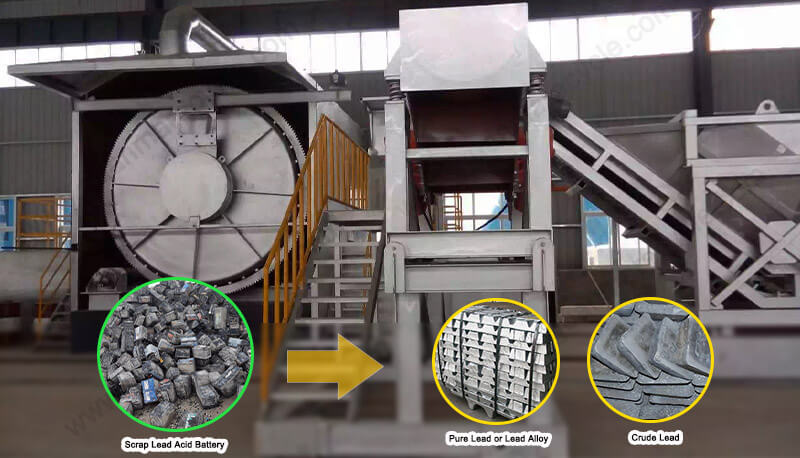

Lead Acid Battery Recycling Plant raw material can be processed is all kind of lead acid battery. Lead acid battery is very common battery, mostly used in the daily life. The final products of separation section is plastic, lead, acid.

Raw Materia

Lead Acid Battery Recycling Equipment processes raw materials: Used lead-acid batteries, Car batteries, Electric car batteries, Electric bike batteries, etc.

Final Product

Lead Acid Battery Recycling Plant Final product: Scrap lead acid battery will be separated by the “Lead acid battery dismantling equipment”. filtered lead mud, grid lead, heavy plastics, light plastics and unclassified materials can be separated. After smelting and refining process, will get pure lead or lead alloy. And plastic also be reused after granulation.

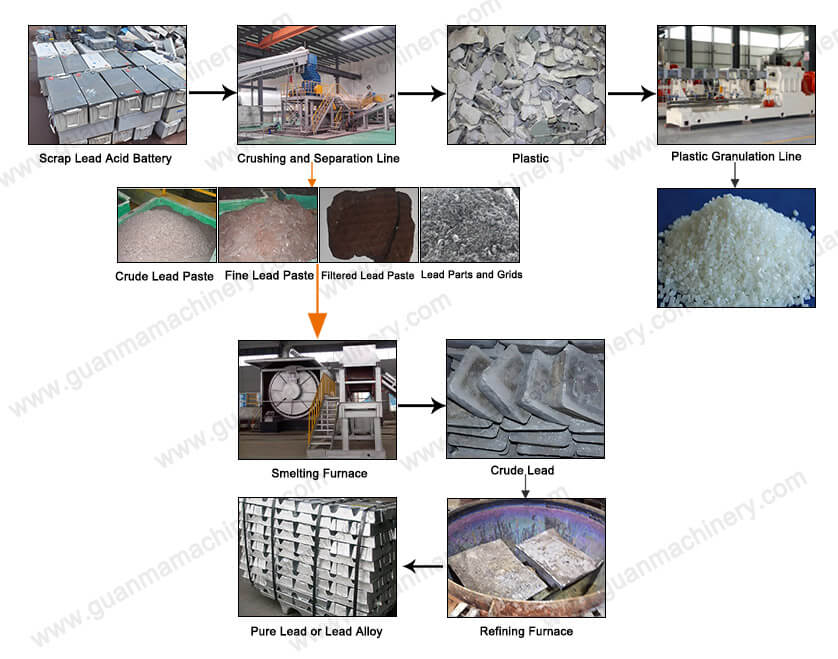

Flow Chart

Used Lead Battery Recycling Process:

The Recycling process of Used Lead Acid Batteries can be categorized to 3 stages :

①Fully Automatic Lead-acid Battery Crushing and Separation Line

There are two options for battery disassembly, crushing and separation: using a lead-acid battery disassembly machine or using a lead-acid battery crushing and Separation line. After disassembly by the lead-acid battery disassembly line or after crushing and Separation, the lead paste, plastic (PP, PE, ABS), lead column and acid are finally separated.

②Smelting Furnace Process

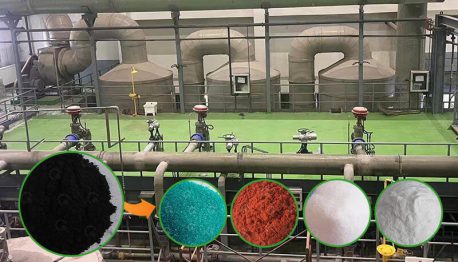

After the separation, will get different kind of lead contend raw material, before smelting, need to do mixed at first, then will transfer to smelting furnace by vibrating screen. After smelting, release lead liquid to crucibles. During machine working, here will have pulse dust collector to collect dust and flue dust.

③Crude Lead Refinery Smelting and Ingot Casting Line

After the smelting process, will get the crude lead, purity is about 95-96%, if want to get higher purity, need do the refining process. Need put crude lead to the refining furnace, then after process will get the purity is 99.9%. Also the finished product can be lead alloy. The ingot casting machine starts casting ingots to make lead ingots.

Technical Parameter

Lead Acid Battery Recycling Plant Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity tons/day | Power/kw | Space Size |

| LABR-50 | 50tons/day | 300kw | 2000m2 |

| LABR-100 | 100tons/day | 500kw | 3000m2 |

| LABR-300 | 300tons/day | 800kw | 6000m2 |

| LABR-500 | 500tons/day | 1000kw | 15000m2 |

| LABR-1000 | 1000tons/day | 1500kw | 20000m2 |

Advantages

Advantages of Our Lead Acid Battery Recycling Equipment

Our lead acid battery recycling equipment boasts several key advantages:

1. Efficiency and Productivity: Our lead acid battery recycling machine is designed for high throughput, ensuring maximum yield with minimal energy consumption.

2. Cost-Effectiveness: Our lead acid battery recycling machine offers a quick return on investment through revenue from recycled materials and reduced disposal fees.

3. Customization: We offer tailored solutions to meet specific client requirements.

Guanma Machinery Lead Recycling Plant Manufacturer provides from plant design and installation to maintenance and technical support in lead battery recycling business. How much does a lead acid battery recycling plant cost? Contact us today to get a quote!

Profit Analysis

Lead Acid Batteries Recycling Line Profit Analysis

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Profit Analysis of Lead Acid Batteries Recycling Line 50tons/day | ||||

| Cost | ||||

| Code | Item | Remark to items | Quty | Total Price(USD) |

| 1 | Raw Material | Car Batteries(Starting batteries) | 50ton | $52,500 |

| 2 | Water Consumption | In Crushing Section | 25m3 | $2 |

| 3 | Electricity Consumption | In Crushing Section | 4598kwh | $1,287.1 |

| 4 | In Reduction Smelting Section | |||

| 5 | In Refinery Section | |||

| 6 | Gas Consumption | In Reduction Smelting Section | 5500m3 | $2,553.6 |

| 7 | In Refinery Section | |||

| 8 | Other | ~ | ~ | $988 |

| Total | $57,330.7 | |||

| Income | ||||

| 1 | Final Products | Lead Ingot (Purity 99.985%) | 25ton | $59,025 |

| Plastic | 4ton | $3,222.4 | ||

| Total | $62,247.8 | |||

| Profit to Process 50tons of Batteries Per Day | ||||

| $4,917.1 | ||||

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)