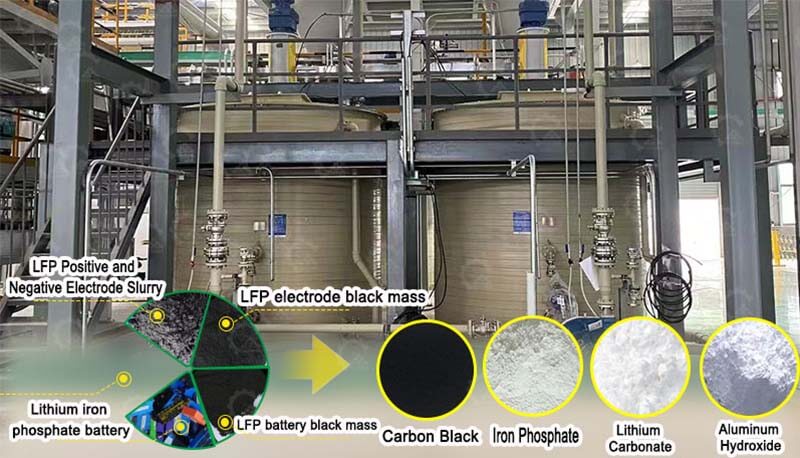

LFP Black Mass Hydrometallurgy Equipment, also known as ”LFP Hydrometallurgy recycling plant” or “Lithium Iron Phosphate (LFP) Battery Recycling Equipment,” are used to recycle valuable metals such as lithium, aluminum, copper and iron from spent lithium iron phosphate batteries.

Usually, Before LFP Black Mass Hydrometallurgy Equipment, the scrap LFP battery need to do pretreatment, such as discharging, dismantling, crushing, and separation to separate the cathode and anode material from separators, adhesive, aluminum foil, copper foil and other components. Then will get black powder rich in LFP.

Raw Materia

The main component of scrap LFP cathode materials is lithium iron phosphate, which also contains carbon black, graphite, copper, aluminum, PVDF, and electrolyte. Valuable elements for recovery include lithium, the final product get is lithium carbonate (Li2CO3). Phosphorus, and iron, where lithium can be recovered directly, and phosphorus and iron can be recovered as ferric phosphate, each holding significant value.

Raw Materials: Lithium iron phosphate batteries, LFP black mass, cathode black mass from LFP electrodes, anode and cathode slurries from LFP batteries

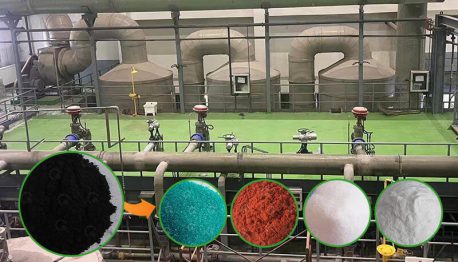

Final Product

Final Product: Carbon black, ferric phosphate(FeSO4), lithium carbonate(Li2CO3), iron/aluminum hydroxide(Fe(OH)3, Al(OH)3)

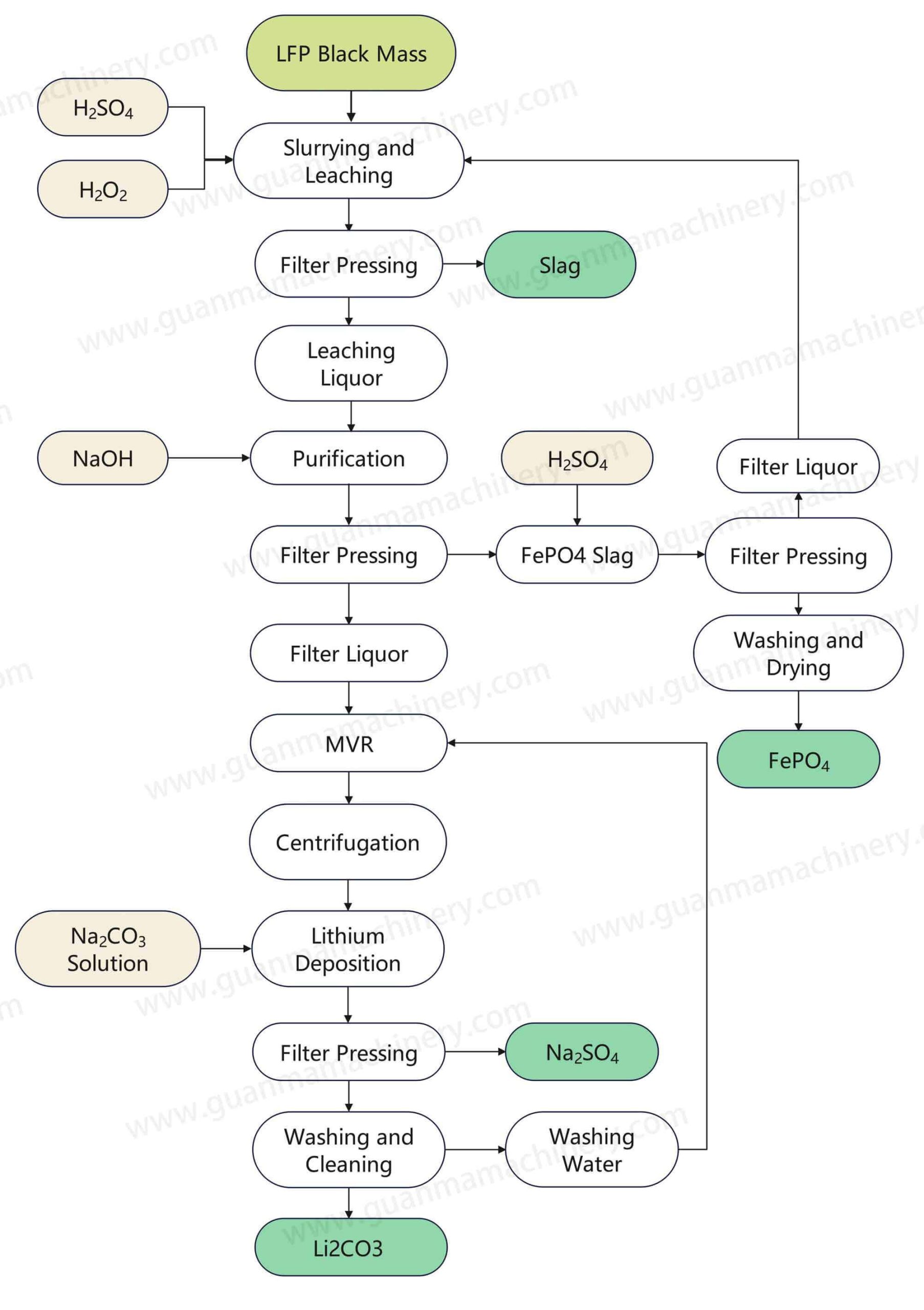

Flow Chart

Hydrometallurgical recovery process of waste lithium iron phosphate

A common method for recycling scrap LFP cathode and anode powder is the wet process for LFP battery recycling.

The hydrometallurgy involves dissolving valuable metals in chemical solutions to concentrate, separate, and extract them, encompassing leaching, solid-liquid separation, metal extraction, solution purification, and wastewater treatment. This method offers high flexibility in raw material selection and can directly process cathode sheets removed from scrap lithium-ion batteries.

Advantages of Wet Process LFP Battery Recycling Equipment:

1. High metal recovery rates.

2. Easy control and high flexibility in the wet process technology.

3. Low energy consumption and low environmental pollution.

Technical Parameter

LFP Black Mass Hydrometallurgy Equipment Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Annual Capacity | Power/kw | Size |

| LBE-1000 | 1000tons | 340kw | About2350㎡ |

| LBE-2000 | 2000tons | 429kw | About3200㎡ |

| LBE-5000 | 5000tons | 580kw | About4352㎡ |

| LBE-10000 | 10000tons | 820kw | About5918㎡ |

| LBE-20000 | 20000tons | 1123kw | About8200㎡ |

Case

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)