The lithium battery recycling machine integrates multiple operations such as charged crushing, low-temperature volatilization, comprehensive sorting, powder removal, and pyrolysis. This results in a highly efficient separation of separators, electrodes, copper and aluminum foils, and black powder. Notably, the separated cathode and anode powders can be subjected to hydrometallurgical extraction for further refinement.Let’s learn more about the lithium-ion battery recycling plant process.

Raw Materia

Lithium ion battery disposal materials include: waste lithium-ion batteries, lithium iron phosphate (LiFePO4), lithium manganese oxide (LiMn2O4), lithium cobalt oxide (LiCoO2) and ternary materials, such as nickel cobalt manganese oxide lithium NCM (LiNi ₓ CoMnO2) and nickel cobalt aluminum oxide lithium NCA (LiNi ₓ CoAlO2); Most of the ternary materials are NCM. The use of ternary materials for the positive electrode is called a ternary lithium battery.

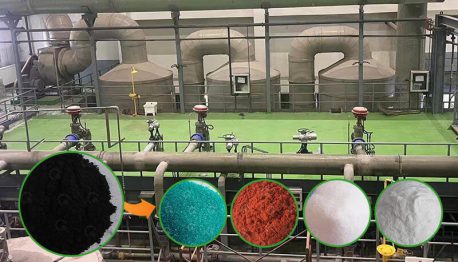

Final Product

Final product of lithium battery recycling machinery

Copper Granules — get from the Battery Anode copper foil or Leftovers.

Aluminum Granules — get from the Battery Cathode aluminum foil, leftovers, and battery case.

Separator: — PP/PE Film, set between battery Anode and cathode.

Black mass: — get from the cathode and anode coating materials, include: Co, Ni, Li, Mn, Graphite, Carbon, PVDF, SBR etc.

Steel: — get from batteries case

Recovery Rate

(1)Copper, aluminum, metal ≥98%

(2)Black mass ≥98%

(3)Separator(PP/PE Film) ≥98%

(4)Copper aluminum contain in black mass ≤1%

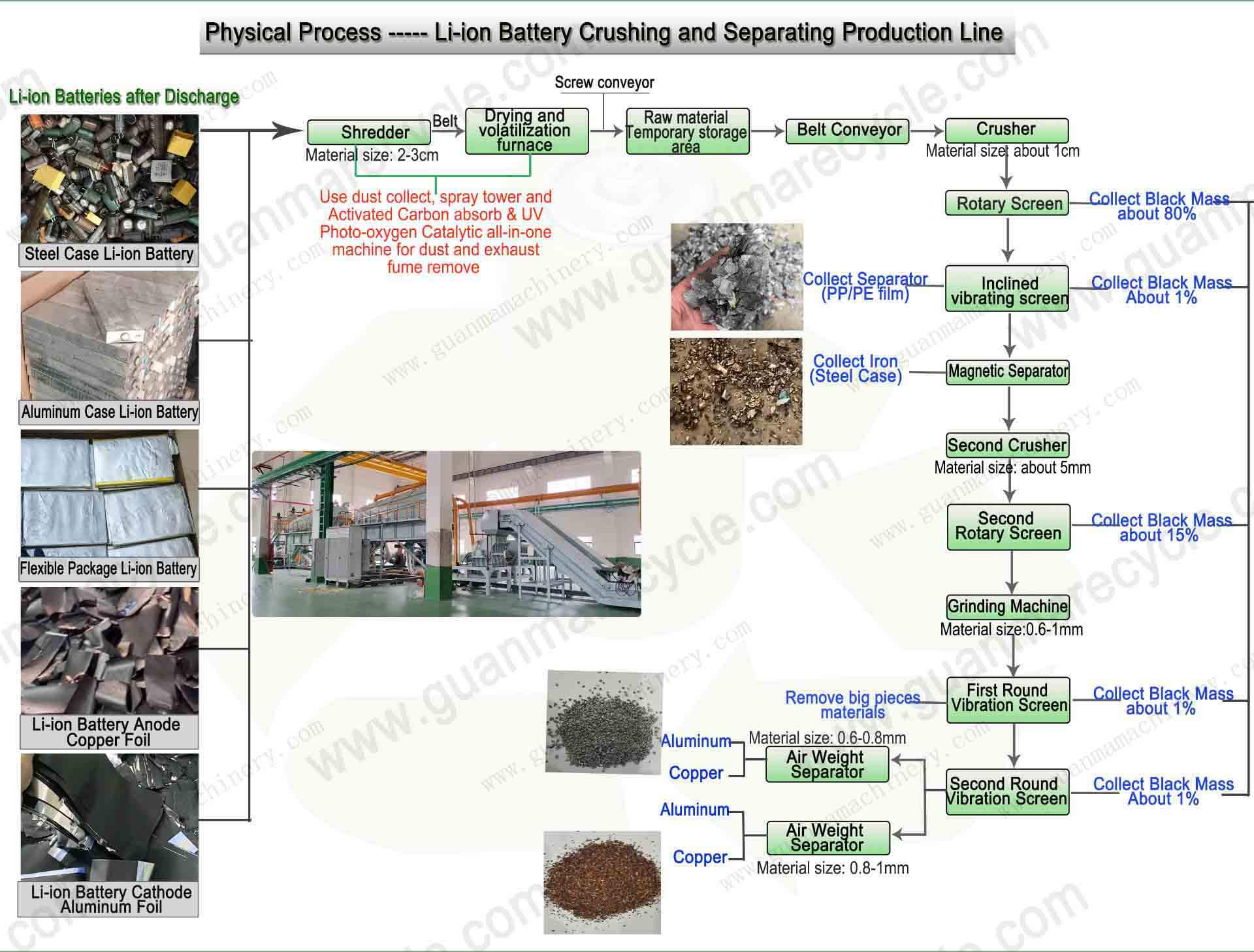

Flow Chart

1. Battery Categorization: Batteries are categorized based on their distinct raw materials.

2. Discharging: Lithium-ion batteries are placed into discharging chambers to ensure complete discharge.

3. Pre-treatment: Post-discharge, the batteries undergo pre-treatment in a battery shredder.

4. Drying: Following pre-treatment, the raw materials are subjected to a drying oven to eliminate moisture and electrolytes, thereby enhancing the separation efficiency.

5. Battery Crushing and Sorting Process:The battery crushing machine primarily employs a hammer mill, utilizing high-speed hammer blades to crush lithium-ion batteries. This process liberates metals and black mass, which are subsequently separated via a drum separator. The procedure is repeated until the final separation of black mass, copper, aluminum, and iron is achieved.

If you want to know more about battery recycling business, you can contact Guanma Machinery lithium battery recycling machine manufacturer!

Technical Parameter

Lithium Battery Recycling Machine Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity kg/h | Power/kw | Size(Length*Width*Height) |

| BRP-500 | 500-800kg/h | 155KW | 20000*6500*6000mm |

| BRP-1000 | 800-1000kg/h | 245KW | 35000*12000*6000mm |

| BRP-2000 | 1000-2000kg/h | 395kw | 55000*15000*6500mm |

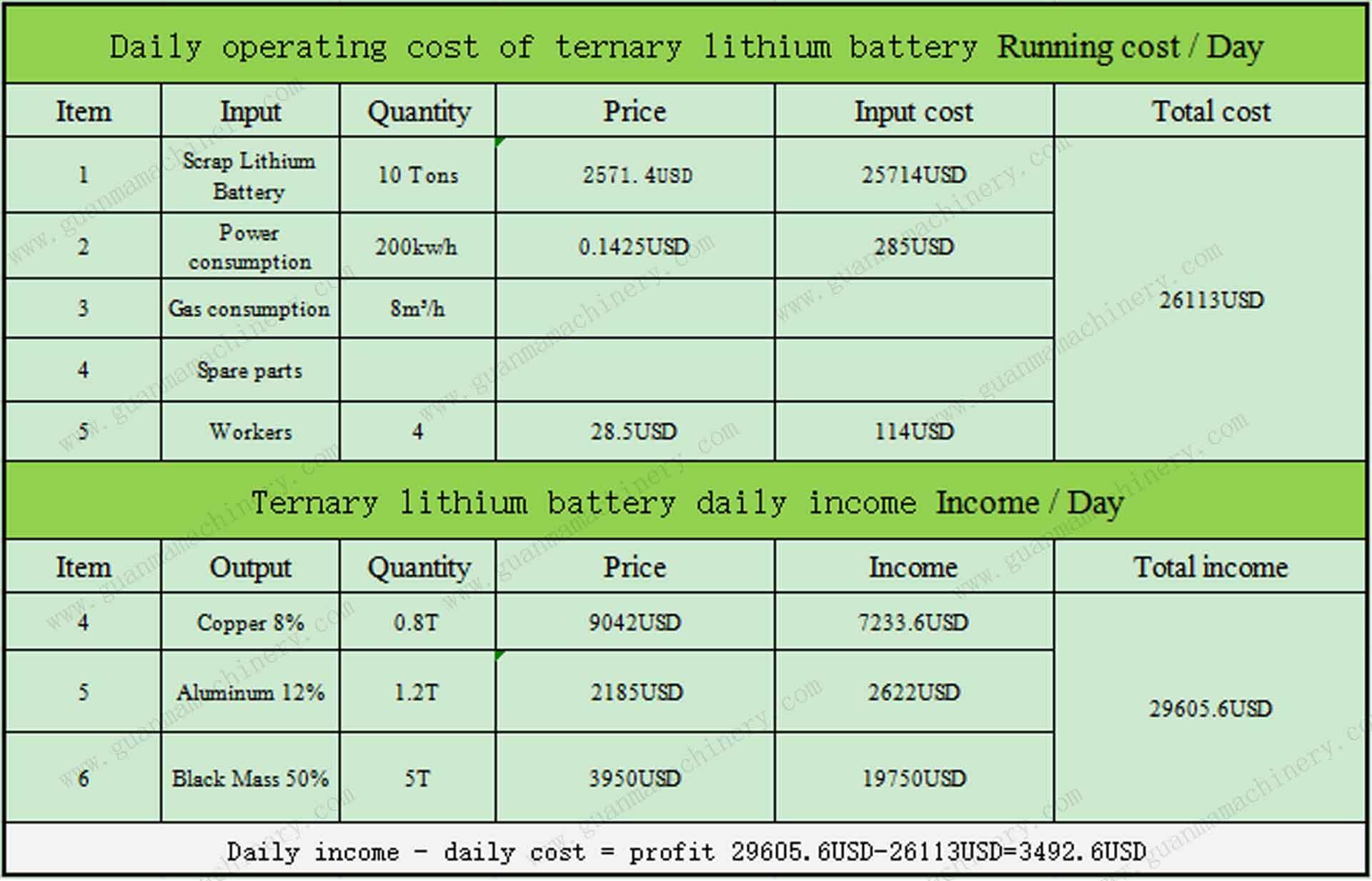

Profit Analysis Table

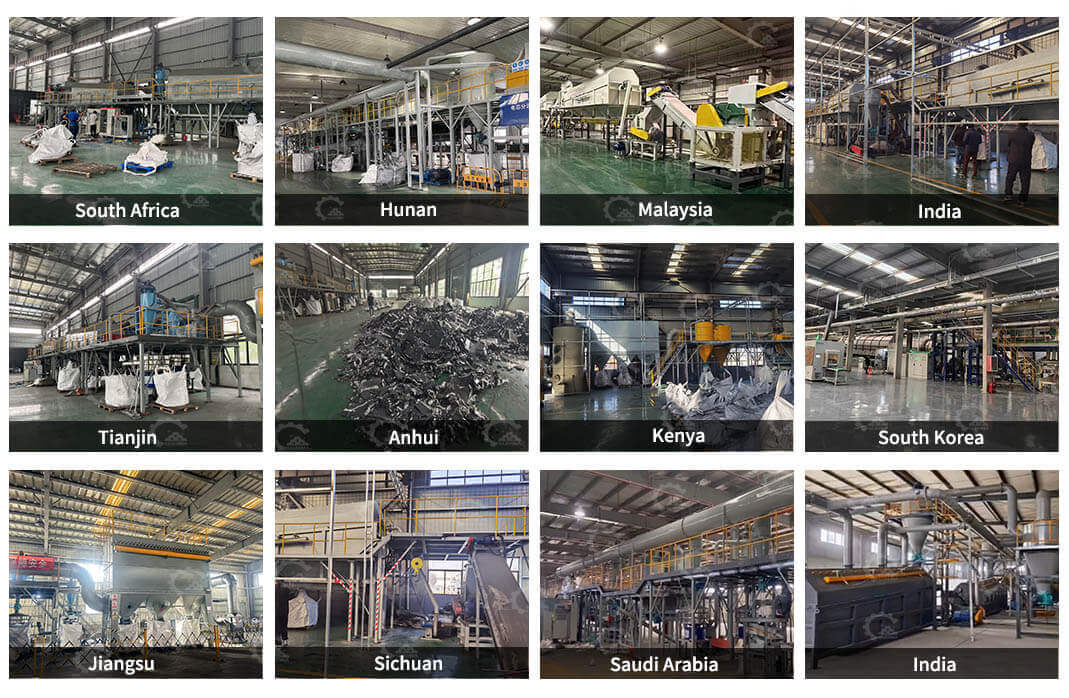

Customer Cases

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)