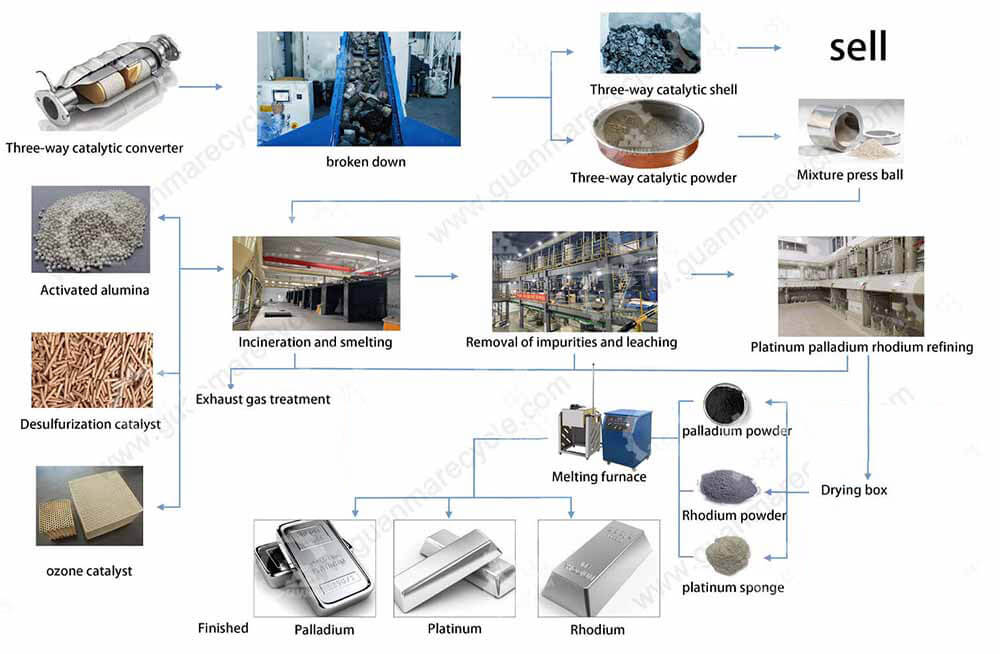

Pt/Pd/Rh Extraction for Scrap Catalytic is very good at extracting the precious metals palladium, platinum and rhodium from the catalyst. The waste catalyst is called a “mobile platinum group metal mine”. Recycling of platinum group metals will form secondary resource regeneration at home and abroad. recycling industry.

Raw Materia

Pt/Pd/Rh Extraction for Scrap Catalytics is used to recycle and reuse waste catalysts such as three-way catalysts, petroleum catalysts, activated alumina, desulfurization catalyst, ozone catalyst, and waste automobile exhaust catalysts.

Final Product

1. Pretreatment system: First, waste catalyst raw materials such as waste automobile three-way catalysts, ozone catalysts, activated alumina, and desulfurization catalysts are pretreated.

2. Fire smelting system: After pretreatment, the waste catalyst containing platinum is smelted and enriched at high temperature and then recycled using traditional methods.

3. Wet extraction system: using acid dissolution, ion exchange, electrolysis, replacement and other processes.

4. Refining system: further process the metal containing a small amount of impurities obtained from smelting to improve its purity.

5. Water treatment system: remove impurities and pollutants in water through chemical methods, such as oxidation,

Reduction, precipitation, etc.

6. Exhaust gas treatment system: It treats exhaust gas and converts harmful substances in the exhaust gas into substances with less impact on the environment through a series of chemical reactions and physical processes, thereby achieving the purpose of purifying the air.

Product Advantages

1. The recovery rate of platinum, palladium and rhodium is high, and the content of each finished product reaches more than 99.99%.

2. Simple operation and high degree of automation.

3. Design a high-level glass trough to reduce employee handling and increase production capacity.

3. The overall equipment investment is small and the operating cost is low.

4. Safety and environmental protection, comply with environmental protection standards.

| Budget List | ||||

|---|---|---|---|---|

| Model | Capacity(kg/day) | Size(Length*Width*Height)(mm) | Power(kw) | Required Finance(USD) |

| PGM-100 | 100-500 | 20000*6500*6000 | 80-150 | 255,000-765,000 |

| PGM-500 | 500-800 | 35000*12000*6000 | 200-500 | 455,000-1,365,000 |

| PGM-800 | 800-1000 | 45000*15000*6000 | 300-800 | 760,000-2,280,000 |

| PGM-1000 | 1000-2000 | 50000*15000*6000 | 800-1000 | 2,200,000-6,600,000 |

| PGM-2000 | 2000-5000 | 55000*17000*6000 | 1500 | 3,250,000-9,750,000 |

| This form is for reference only, the final decision is subject to the customer's proposal | ||||

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)