Guanma Machinery Solar Panel Recycling Machine Manufacturer provides two processes for recycling waste solar panels: crushing process and pyrolysis process. The crushing process is suitable for single-glass solar panels, with low cost, but low silver recovery rate. The pyrolysis process is suitable for double-glass solar panels, with large processing capacity, high purity and high recovery rate. Customers can choose the process route according to their own raw materials.

Guanma Machinery optimizes solar panel recycling machine cost through energy-saving design, scalable capacity, and minimal operating expenses. Explore solar panel recycling solutions now.

Raw Materia

Thin Film Solar Panels

Monocrystalline Silicon Solar Panels

Polycrystalline Silicon Solar Panels

Decommissioned Solar Modules

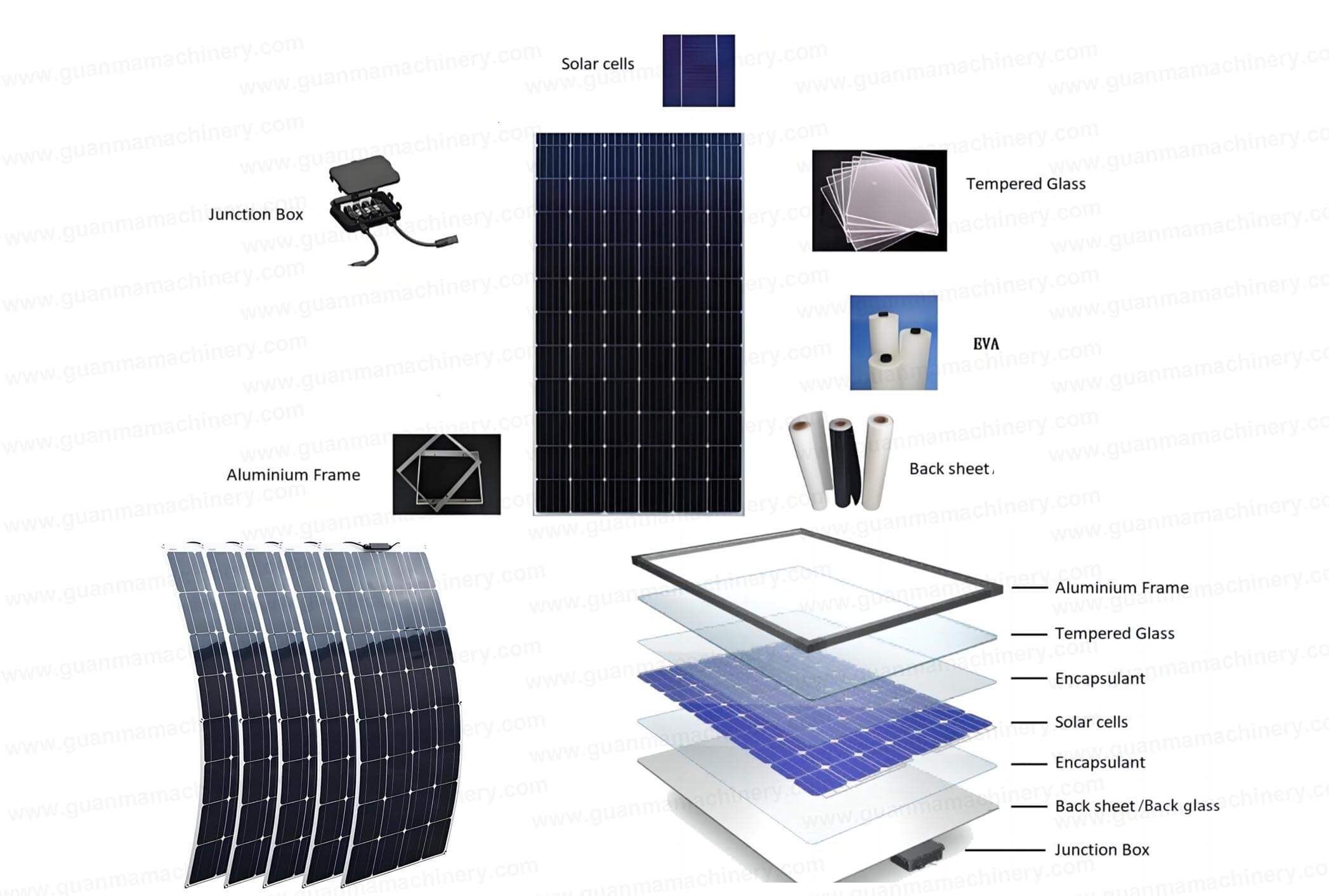

Composition Analysis of Solar Panels

| Composition | Proportion |

| Glass | 70-80% |

| Aluminum Frame | 10-15% |

| Silicon Cell | 5-10% |

| Backsheet | 5% |

| EVA | 5-7% |

| Conductive Materials | 1% |

| Junction Box | 2-3% |

| Composition | Proportion |

| Glass | 65-70% |

| Aluminum Frame | 10-15% |

| Silicon Cell | 5-8% |

| Backsheet | 5% |

| EVA | 6-8% |

| Conductive Materials | 1% |

| Junction Box | 2-3% |

| Composition | Proportion |

| Glass | 60-75% |

| Aluminum Frame | 10-15% |

| Silicon Cell | 5-10% |

| Backsheet | 5% |

| EVA | 5-7% |

| Conductive Materials | 1% |

| Junction Box | 2-3% |

Our solar panel recycling machinery handles:

Solar panel recycling equipment can process raw materials: Crystalline silicon (c-Si) PV panels, Thin-film solar panels (CdTe, CIGS), Broken or decommissioned solar modules, Glass, EVA film, junction boxes, and aluminum frames.

Final Product

Aluminum Frame

J-Box

Glass Granule

Silicon Slice

Silicon Powder

Plastic Powder

Copper Powder

Silver Ingot

Aluminum frame removal rate ≥ 99%, recycling purity ≥ 98%.

Glass removal rate 85-95%, recycling purity ≥ 90%.

Metal particle (copper) recovery rate ≥ 95%, recycling purity ≥ 95%.

Plastic powder recovery rate ≥ 95%, recycling purity ≥ 90%.

Silicon recovery rate 95%, appears in the form of a mixture of plastic powder, glass powder, etc., with a silicon content of about 45%.

Flow Chart

1. Frame Removal Machine: The fully automatic pv panel frame removal machine uses the hydraulic disassembly principle to efficiently and safely remove the aluminum frame of the photovoltaic panel for recycling. Remove aluminum frames and junction boxes.

2. Glass Removal Machine: The solar panel glass removal machine is a device specially used to separate the glass layer of photovoltaic panels from other components (such as silicon circuit chips, packaging materials, backplanes, etc.).

3. Crushing and Sorting Production Line: The crushing and sorting production line mainly processes the back panel raw materials mainly composed of copper, silver and silicon powder after removing the aluminum frame and glass. After the main pre-treatment crushing, crushing and grinding, the plastic and metal are separated.

4. Pyrolysis Process Line: After removing the aluminum frame and glass, the remaining materials (mainly silicon, metals, cables, etc.) are directly fed into the pyrolysis treatment line. producing combustible gases, liquid oil, and solid residues (such as metal oxides, silicon powder, etc.)..

5. Extraction of Precious Metal: After crushing or pyrolysis, the metal content mainly is copper, also will have some silver mixed in silicon. Will use silver electrolytic refining equipment to extraction silver, to get purity silver.

| Technical Parameters | Specification |

| Capacity | 40-70PCS/h |

| Raw Material Size | Length(mm):1000-2400 Width(mm):800-1300 |

| Power | 4Kw |

| Size of Machine | 2100X2140X2130mm |

| Operating Mode | Automated/Semi-automated |

| Weight | 1200KG |

| Technical Parameters | Specification |

| Capacity | 40-70PCS/h |

| Raw Material Size | Length(mm):1000-2400 Width(mm):800mm-1300mm |

| Power | 30Kw |

| Operating Mode | Automated |

| Weight | 7.5T |

| Finished Product | Separation Rate | Purity |

| Mixed Metal | 95% | 95% |

| Plastic | 95% | 90% |

| Silicon | 95% | – |

| Model | Capacity kg/day | Power/kw | Size(Length*Width*Height) |

| SPL-300 | 1-2T/H | 350Kw | 32*7*6m |

| SPL-500 | 2-3T/H | 400Kw | 40*8*6m |

| SPL-2000 | 3-5T/H | 480Kw | 48*10*6m |

| This data is for reference only. Please consult Guanma Machinery for detailed configuration. | |||

| Model | Capacity kg/day | Power/kw | Size(Length*Width*Height) |

| SER-20 | 20kg | 5 | 1500*700*1850 |

| SER-50 | 20-50kg | 10 | 1600*800*1900 |

| SER-100 | 50-100kg | 15 | 570*840*1200 |

| SER-200 | 100-200kg | 25 | 1200*840*1300 |

| SER-300 | 200-300kg | 39 | 1930*840*1300 |

Technical Parameter

Solar Panel Recycling Machine Technical Parameters

Working voltage can be customized, and if you have other requrement and want to know more details, please contact us.(The data in this table are for reference only)

| Model | Capacity kg/day | Power/kw | Size L*W*H(m) |

| SPR-500 | 100-500kg | 138kw | 30*7*5m |

| SPR-1000 | 500-1000kg | 285kw | 45*7*5m |

| SPR-2000 | 1000-2000kg | 380kw | 65*20*6m |

| SPR-3000 | 2000-3000kg | 485kw | 100*25*6m |

| Note: Capacity can be customization(The data in this table are for reference only) | |||

Advantages

✅ High Efficiency: Processes 200-1,000 kg/hour. (Customizable capacity).

✅High Recovery Rate: 95%+ Material Recovery Rate.

✅ Low Energy Consumption: Advanced thermal management reduces power use by 30%.

✅ 24/7 Support: From a trusted Solar Panel Recycling Machine Manufacturer.

As Solar Panel Recycling Machine Manufacturer, we combine innovative technology with affordable solar panel recycling machine prices. Our systems are engineered for durability, scalability, and compliance with global e-waste regulations. Partner with us to transform solar waste into profit!

Contact Guanma Machinery Today for a detailed quote, process demo, or customized solar panel recycling machinery solutions!

Contact Us

Please specify your requirement by referring to the following aspects:

1-What kind of raw material do you want to process?

2-How many tons raw material do you want to process per day?

3-When will you want to start this project?

4-How is your budget of machine?

5-Which point that you really focus on?(We have customized service for each client)