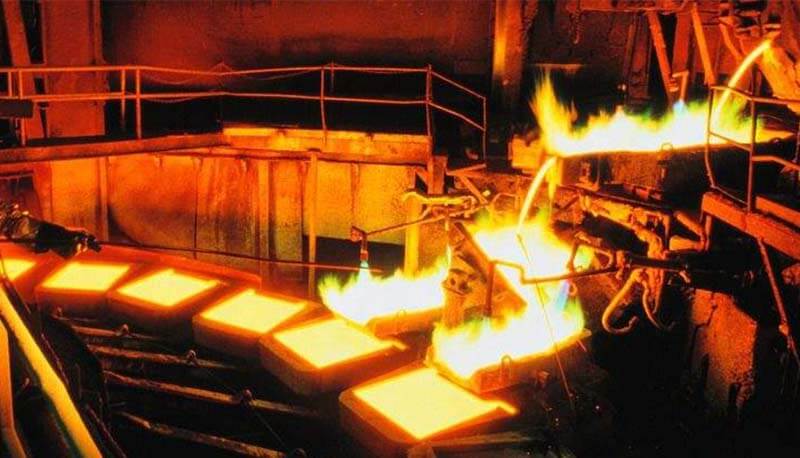

Pyrometallurgical Refining of Blister Copper

Blister copper produced from the matte blowing process contains 98.5% to 99.5% copper, with 0.5% to 1.5% impurities and a certain amount of precious metals that have recovery value. The impurities mainly consist of nickel, lead, arsenic, antimony, bismuth, iron, sulfur, and oxygen, which need to be removed, while the precious metals should be recovered. Therefore, it is necessary to refine the blister copper.

Process Flow for Pyrometallurgical Refining Copper:

1. Direct Production of Commercial Copper: In this process, blister copper undergoes pyrometallurgical refining directly to produce commercial-grade copper. However, this method does not allow for the recovery of valuable metals such as gold and silver, and the product can only be used in certain sectors of mechanical engineering where requirements are lower.

2. Direct Casting into Anodes for Electrolytic Refining: Blister copper is cast directly into anodes for electrolytic refining. Due to the uneven surface of the raw copper, numerous pores, slag inclusion, and high oxygen and sulfur content, this leads to low current efficiency in electrolysis, high energy consumption, excessive net liquid volume, anode slime, and residual anode rate, resulting in lower quality electro-refined copper.

3. Pyrometallurgical Refining Followed by Electrolytic Refining: This involves first refining the blister copper through pyrometallurgical means before casting it into anodes for electrolytic refining. This process yields high-purity copper with excellent properties and allows for the recovery of valuable metals contained within. Most plants adopt this flow.

For more information on the pyrometallurgical refining of blister copper, you may contact Guanma Machinery!