Waste Lithium Iron Phosphate Battery Recycling Machine

Currently, the most widely used power batteries in new energy vehicles are nickel-cobalt-manganese (NCM) ternary batteries and lithium iron phosphate (LFP) batteries. Waste Lithium Iron Phosphate Battery Recycling Machine mainly includes two methods: cascade utilization and disassembly recycling.

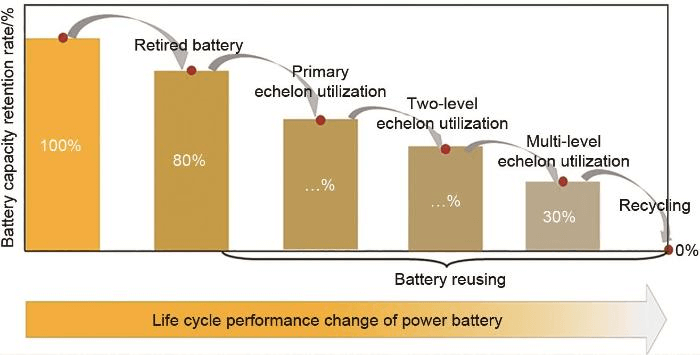

Battery Lifecycle Performance Changes

Whether retired LFP power batteries can be cascaded and their application fields mainly depend on the remaining capacity of the battery. When the battery’s remaining capacity is between 30% to 80%, it can undergo cascade utilization; when it falls below 30%, it does not meet the standards for cascade utilization and should be recycled through disassembly.

Pre-treatment of Waste Batteries

The pre-treatment process effectively improves the recovery rate and reduces energy consumption in subsequent processes, aiming to safely and efficiently separate different components and active materials of the battery.

Waste Lithium Iron Phosphate Battery Recycling Machine Process

Battery Discharge

There is often a risk of spontaneous combustion during the recycling of lithium-ion batteries, thus requiring initial discharge deactivation treatment. Due to the significant differences in size and packaging of waste batteries from various sources, it is necessary to dismantle them to remove the outer packaging to facilitate subsequent processing.

Disassembly

After disassembly, the power batteries need to go through crushing to release the active substances on the electrodes, a process crucial for subsequent hydrometallurgical procedures.

Crushing

Following crushing, more refined separation methods are required, such as magnetic separation, eddy current separation, electrostatic separation, gravity separation, and froth flotation.

Vibratory Screening

Magnetic separation after vibratory screening can usually separate aluminum collectors containing active substances, anodes, steel shells, and plastic packaging.

Guanma Machinery Waste Lithium Iron Phosphate Battery Recycling Machine Manufacturer

Guanma Machinery has developed a waste lithium iron phosphate battery recycling machine, achieving safe battery discharge, efficient electrolyte recovery, and precise separation of positive and negative electrode materials with a separation efficiency ≥99%. This avoids using large amounts of acids and alkalis, causes no secondary pollution, and truly realizes environmental protection, harmlessness, and safety in the process of handling waste lithium batteries.