Copper refining plays a crucial role in ensuring the production of high-quality copper, which is widely used in various industries, including electronics, construction, and energy. One of the most effective methods of copper refining is through electrolysis. But what exactly does this process entail, and why is it so widely used? In this article, we’ll explore the electrolysis process in copper refining and how it helps to produce high-purity copper.

What is Electrolysis?

Electrolysis is a process where electrical current is used to drive a non-spontaneous chemical reaction. In simpler terms, it is a method of using electricity to separate elements from compounds. The process involves two electrodes: an anode (positive) and a cathode (negative), which are submerged in an electrolyte solution. The electrolyte facilitates the movement of ions, which is crucial for the electrochemical reactions that take place at the electrodes.

Electrolyte and Electrodes in Electrolysis

The electrolyte is typically a liquid or gel that conducts electricity due to the presence of ions. In copper refining, sulfuric acid is commonly used as the electrolyte. The electrodes are usually made of conductive materials such as graphite or copper, which allow the flow of electric current.

Electrolysis Process in Copper Refining

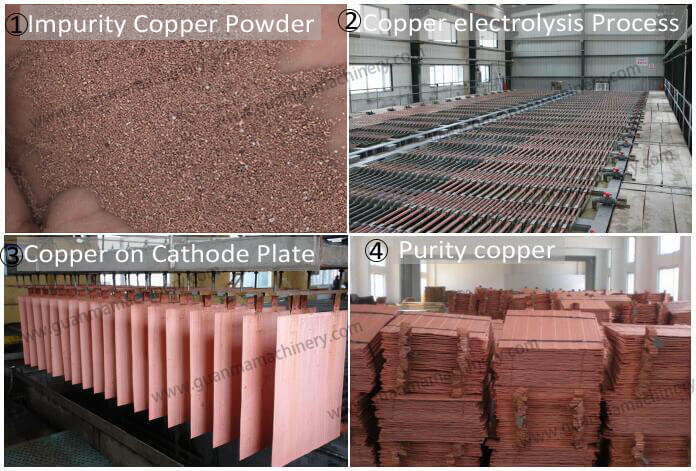

The process of refining copper through electrolysis starts with impure copper being used as the anode in an electrolytic cell. The copper ions are dissolved into the electrolyte, and copper metal is deposited at the cathode.

Basic Steps of Electrolysis in Copper Refining

Anode Reaction: Impure copper at the anode dissolves, releasing copper ions (Cu²⁺) into the electrolyte solution.

Cathode Reaction: Copper ions in the electrolyte move towards the cathode, where they gain electrons and deposit as pure copper.

Purification: As the copper at the anode dissolves, impurities that do not dissolve in the electrolyte, such as gold and silver, accumulate as anode mud or sludge.

Applications of Electrolytic Copper

Electrolytic copper, with its high purity, is essential in several high-tech industries. The refining process ensures that the copper used in electrical components and electronic devices is free from impurities that could negatively affect performance.

Electrolysis is a pivotal process in the refining of copper, allowing for the extraction of high-purity copper from ores and impure metal. The efficiency of the process and the purity of the final product make copper a cornerstone of the copper industry.

FAQs

1. What is the main principle behind copper electrolysis?

Copper electrolysis works by passing an electric current through a solution containing copper ions, which causes copper to dissolve from the anode and deposit onto the cathode. This process results in the purification of copper.

2. How pure is copper obtained after electrolytic refining?

The copper obtained after electrolytic refining is typically 99.99% pure, making it ideal for use in high-precision electrical applications.

3. What chemicals are used in the electrolytic cell for copper refining?

Sulfuric acid and copper sulfate are commonly used as the electrolyte solution in the copper electrolysis process.

4. How long does the copper electrolysis process take?

The duration of the copper electrolysis process depends on the size of the operation and the current used, but refining can take several days to weeks to achieve the desired purity.

5. Can electrolysis be used to refine other metals?

Yes, electrolysis can be used to refine other metals, such as gold, silver, and zinc. The electrolysis process is versatile and can be applied to many different types of metals.